Heat exchanger for sauna stove underfloor heating. Warm floor in the bathhouse from the sauna stove. Flooring installation

Home improvement floor systems heating, as a rule, allows us to warm the rooms of our apartments. But hidden heating units can also be used to create the most comfortable conditions in places such as steam rooms, saunas and baths. And how to make a heated floor in a bathhouse from a stove, the diagram in which plays an unimportant role, you will learn from our article.

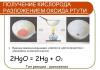

System Features

Due to the fact that not a boiler, but a stove will be used as a heating installation, a heat exchanger should be installed on top, above the firebox. As a rule, for these purposes, the most common tank made of stainless steel or any other metal that is not prone to corrosion upon contact with moisture is used. You can also take a register from pipes. There is no fundamental difference in this. From the heat exchanger for the heated floor installed above the stove, a pipeline is laid to those rooms where it is necessary.

In order for the “spent” coolant to be able to return to the exchanger again, a small circulation system will also be required. pumping unit. Without it, the structure will be able to fully function, provided that the stove is located below the level of the floor surface. In addition, pipes of a non-standard diametrical size for such heating blocks will also be required. So, to install a hidden heating block that will be powered from the furnace, you need to purchase Ø24 mm pipes, whereas when laying a pipeline under standard conditions, a Ø16 mm pipe is used.

Organization diagram

The main feature of the floor-standing stove heating system is the impossibility of adjusting the temperature.

The recommended temperature of the structure in such conditions is 40°C, while the furnace will supply almost boiling water into the main line, which is not acceptable for the coolant. Therefore, in such cases, it is advisable to equip the system with a mixing unit, through which mixing will be carried out hot water from the furnace and the cooled source from the “return”.

Since it is not possible to install a large heat exchanger in the furnace, an accumulator tank should be installed near it, which is connected to the heat exchanger via steel pipes.

It is advisable to install warm floors in the bathhouse in all rooms

Pros and cons of the design

Before answering the question, how to make from a stove water heating, let's look at the advantages and disadvantages of such a setup.

So let's start with the positives:

- absence of electromagnetic radiation, as happens when a room is equipped with electric floors;

- environmental safety;

- the possibility of creating camphor temperature conditions in the steam room;

- cost-effectiveness (not only does the installation of electric floors cost several times more, but you also have to pay considerable monthly electricity bills);

- eliminating the appearance of fungal infections and mold;

- preventing the appearance of cold drafts, since the energy from the heating element will begin its smooth upward movement, uniformly heating the area of the entire steam room.

As for the disadvantages, these include:

- The need to drain the heat source from the system into winter time year, which will prevent pipeline rupture due to an increase in the volume of frozen water.

- A considerable amount of energy is spent heating the battery tank, which causes a decrease in the efficiency of the furnace.

- Simultaneous heating of several rooms, for example, steam room, dressing room, shower room, etc. Large volumes of coolant are required, which significantly increases the time for its complete heating.

- Inability to install leaking floors in the bath room. As a rule, many baths are equipped with such systems, which simplifies the draining of excess liquid. In the case of warm floors This is absolutely impossible to do, because all insulation and thermal insulation materials will be completely wet and will not be able to fully fulfill their purpose.

VIDEO: Kamenka stove with heated floor in the steam room

Tips for arranging floor heating blocks in a bathhouse

To organize an efficiently operating heating unit in a steam room, you must adhere to several important recommendations, which were proposed by experienced specialists working in this field of activity.

This is what the “pie” of a water heated floor looks like

Concrete screed

The concrete screed base is the best option floor finishing of a bath room, because it allows you to significantly save on materials, but at the same time has high performance moisture resistance due to the use of cement.

However, such a floor can only be used after the solution has completely hardened. As a rule, this can take from two to four weeks, it all depends on the conditions in the room itself. In addition, if the line is damaged, it is extremely difficult to localize the leak, which requires complete dismantling of the screed.

Polystyrene boards for thermal insulation

It is best to use special polystyrene-based boards as a thermal insulation material. They are equipped with a reflective metallized layer and have special internal grooves for easy media placement.

Installation of communications in a wooden floor

Installation sauna stove on a wooden floor and installation of a main line in a wooden floor structure is also possible. But in this case, it is necessary to carry out an accurate calculation, with the help of which it will be possible to determine the location of the holes in the joists for laying the coolant. But as far as maintainability is concerned, such systems are much better than those installed in a concrete tie structure.

Stages of installing a water heated floor

The efficiency of its operation and, accordingly, comfort in the environment depend on how correctly and accurately you can assemble the water heating unit. bath room.

So, the floor heating installation in the bathhouse looks like this:

- first layer - rough screed, thanks to which it is possible to exclude possible distortions and unevenness of decorative flooring;

- Next comes a waterproofing sheet, which prevents condensation from accumulating during operation of the element;

- lay on top of the waterproofing thermal insulation material, which will allow all the energy to be directed into the heated room, eliminating all heat loss;

- the fourth stage is laying a reinforcing mesh that protects the layer of insulating fabric;

- Next you need to do the installation metallized substrate, which will reflect energy into the room without letting it through to the walls and interfloor ceilings;

- the sixth stage is laying the main line, which is best laid according to the “Snail” pattern, due to which the heating of the surface is more uniform

.jpg)

- a finishing screed is poured over the pipeline with a slight slope towards the drain hole;

- The finishing touch is laying the decorative covering.

As you can see, floor heating from a stove is not difficult to arrange in a bathhouse. This method will allow you to save money on the purchase of a heating boiler and energy costs. As a result, the bathhouse will have a favorable microclimate and a comfortable floor.

VIDEO: Warm floors in a bathhouse from a wood-burning boiler

The organization of heated floors in the bathhouse is necessary to create a comfortable microclimate in the dressing room. A wood stove can be used as a heat source. But for this you need to select a circuit and components.

Warm floor in the bathhouse from a buffer tank

A convenient but labor-intensive option for heated floors in a bathhouse is the use of a buffer tank. This method is used when there are several heating circuits. Conditions – there is space for installation buffer capacity. Its capacity is 500-1000 liters. The advantage of the system is the ability to use warm water for the shower.

- heated floor area – from 40 m²;

- power wood stove– from 15 kW;

- the ability to regulate the temperature of the coolant - mixing unit;

- system for quickly adding water to pipes.

Room area with buffer capacity– from 15 m². This is necessary for comfortable maintenance and repair of heating elements.

Scheme

For fast heating water is installed in a wood stove. It could be homemade design lattice or capacitive type. It should be located in the firebox, in the zone of highest temperature. The inlet and outlet pipes must be metal, installed shut-off valves, thermometer and pressure gauge.

Arrangement of heated floor elements, starting from the supply pipe.

- Connection to buffer tank.

- The tank contains a heat exchanger for indirect heating water.

- From the tank there is a supply pipe to the mixing unit.

- The mixing unit consists of a three-way valve and a circulation pump.

- From the collector comes the wiring of heating circuits - from 1 to 6 pcs.

- Return the cooled coolant to the storage tank.

To automate the operation, you can connect to a three-way valve. When the maximum temperature is reached, it will turn on, the hot water will begin to mix with the cooled water from the return pipe.

To drain the coolant, a tap is installed in front of the collector. To add water to the system, a shut-off valve is placed on the supply pipe. Installation of security systems is required - expansion tank, drain valve and air vent.

Design Features

- small floor area;

- wood boiler power – up to 10 kW;

- need to save space.

The layout of pipes and installation of components depends on the design of the bathhouse - the location of the boiler, dressing room. It is compiled individually, but taking into account technical requirements and standards.

Scheme

A difficult task for such a scheme is installing the supply pipe into the boiler furnace. In or models you need to drill a hole with a diameter equal to the cross-section of the pipe. IN brick oven Part of the firebox is disassembled to install the pipe. It is important to ensure the tightness of the connection; there should be no gaps between the pipe and the wall of the furnace.

The order of the components.

- Coolant supply pipe.

- Thermometer, pressure gauge (optional).

- Air vent and water release valve.

- Circulation pump.

- Laying pipes in the floor.

- Connection to expansion tank.

- Return of cooled water for heating.

The pipes for connecting to the boiler are metal, diameter – 12-20 mm. It affects the heating area, and as a result, the rate of increase in coolant temperature. If the layout allows, you can make a mixing unit. This will allow you to automatically regulate the degree of heating of the coolant. But for this, the supply and return lines must be located nearby.

Advantages and Disadvantages

The difficulty of such a warm bath floor is the inability to control the temperature of the water in the pipes. Due to the small area of the line in the furnace, heating occurs slowly; it can only be regulated by a circulation pump. Prohibited use open system heating, as there is a possibility of air pockets. This will cause overheating and damage to the pipeline.

Advantages of single-circuit floor heating:

- Low consumption of pipes and components.

- Not needed special tools And additional blocks– mixing, automatic addition of water to the system.

- Easy maintenance and repair.

To quickly increase the air temperature in the steam room, part of the pipeline can be located under the shelves. It should not come into contact with wooden elements.

Warm water floors from a wood stove in the house

This heating scheme can be implemented for a private home. Condition - the power of the furnace must ensure heating of the entire coolant long time. To do this, you need a good indirect heating tank of at least 1000 liters. Pipes made of cross-linked polyethylene with an oxygen barrier. Their installation is done on a special substrate.

Features of organizing a heated floor system from a stove in a private house:

- collector wiring is required;

- pressure stabilizer if two or more manifolds are installed;

- the maximum length of one circuit for a 16 mm pipe is up to 70 m.

It is important to ensure uniform heating of water in all circuits. To do this, we need collectors with thermostats for each section of pipelines.

Properties warm air are such that it rises upward, so it may be hot in the bathhouse, but the floor will remain cold.

Such changes are uncomfortable for many people, so you can make a heated floor system, which is widespread today.

It is easier and more expedient to make a heated floor in a bathhouse from a stove than to use electric floors. After studying the material in the article, you will be able to find out the features of the system and installation methods.

General information about the system

The water in the water circuit pipes will be heated by the stove

The water in the water circuit pipes will be heated by the stove For a heated floor in a bathhouse, there is no need to install a boiler, since the heating will come from the stove. To do this, a heat exchanger should be made from a metal tank above the firebox.

From it it will be possible to install water heating on the floor in those rooms where it is necessary. Additionally, you will need to install a pump to circulate water in the pipes.

Since it will not be possible to install a volumetric heat exchanger in the furnace, you should additionally place an accumulator tank next to it and connect it to the heat exchanger using steel pipes. To reduce heat loss, insulation is laid on the floor so that it can properly reflect it and the rooms will have the required temperature.

The main problem with a water-heated floor from a stove is the inability to regulate the temperature. For heating, it is recommended to heat the floor to 40 degrees, but in the bath the water gets hotter and you will need to additionally install a mixing unit.

To protect the floor itself from moisture, a standard cement-sand screed, and tiles are used as flooring.

Before installing the system, you need to familiarize yourself with the pros and cons, which are given in the table:

| № | Advantages | Flaws |

|---|---|---|

| 1 | There is no electromagnetic radiation, unlike the electrical system. | In winter, it is necessary to drain the water so that the pipes do not burst from frozen water or the stove must be constantly heated. The best option– change the water to antifreeze. |

| 2 | Environmentally friendly and harmless to health. | Heating the battery tank will require a lot of heat, making the furnace less efficient for its main purpose. |

| 3 | Comfortable conditions are maintained in the bathhouse, the floor remains warm. | To heat floors in several rooms, you should install a large coolant, which will increase the warm-up time. |

| 4 | Economical. |

Warm floors can be made using several types of materials and devices, which are presented in the table:

| Name | Advantages | Flaws |

|---|---|---|

| Concrete screed - for a bathhouse ideal option. Filling is simple and does not require special skills. | Saves money on building materials, and due to cement, the floor will be resistant to moisture. | You can use the floor a month after pouring, but if the pipe is damaged, you will have to remove the entire screed to be able to determine the location of the leak. |

| Polystyrene boards are easy to use. | Each plate already has a layer of foil, which allows it to reflect heat, and they are also equipped with places for fixing pipes. | It is necessary to additionally fill the screed. |

| Heating pipes in a wooden floor. | High maintainability. | Needed accurate calculations to determine the laying of the pipeline. |

To insulate the system, you can use any thermal material: mineral wool, expanded clay, polystyrene foam and other types.

Floor installation and preparation

A concrete screed is poured over the laid materials and pipes

A concrete screed is poured over the laid materials and pipes

The warm floor in the bathhouse from the stove according to the scheme is made from the following layers:

- A layer of waterproofing that will protect the floor covering from condensation collection.

- The thermal insulation layer will retain the heat that can pass through the ceilings.

- To protect the insulation, a reinforcing mesh is laid.

- A layer of reflective materials with foil that will reflect heat into the room.

- A pipeline laid in the form of a spiral to uniformly heat the area.

- Screed for leveling surfaces with small slopes towards the drain hole.

- Laying the final floor covering.

If the floor will be laid on open land, then before the waterproofing layer you should pour a cushion of gravel and sand, and also lay a layer of expanded clay. Expanded clay will additionally perform a thermal insulation function.

Before any work, preparation is necessary. For a floor that will be heated by a stove, you should prepare a base and make a drain. The work is carried out as follows:

Before any work, preparation is necessary. For a floor that will be heated by a stove, you should prepare a base and make a drain. The work is carried out as follows:

- It is necessary to remove the soil between the foundation, under the washing room and compact the surface. You will need to first lay a pipe in the wall to drain water into the sewer.

- A backfill of sand and gravel 15-20 cm high is made, after which the cushion is compacted.

- The base is insulated using expanded clay. The layer of material is 15-20 cm depending on the climate.

When preparing the surface, you need to remember the slope for the drainage.

Step-by-step installation instructions

Heating the floor in the bathhouse using the heat of the stove is a profitable step

Heating the floor in the bathhouse using the heat of the stove is a profitable step

The base of the bathhouse is ready, which means it’s time to start laying out the pipes. For this you can use like copper pipes, and metal-plastic. The installation process is as follows:

- Initially installed waterproofing material. For this, roofing material is used, which is laid in two layers. Its joints are glued together with mastic, and all strips of material must be perpendicular to each other.

- Next, thermal insulation is laid.

- The next step is to lay the reinforcing mesh, which will protect the insulating materials.

- Pipes for floor heating are placed on top of the grid and connected to check their functionality and the presence of possible leaks.

- When all the materials are laid, you can begin to pour the screed over the entire area of the room. A damper tape is first glued around the perimeter of the rooms, which will prevent the floor from deforming due to temperature. Any type of mixture can be used for screeding.

- The floor filling is leveled along the beacons and the angle to the drain is maintained.

- The water-heated floor is almost ready; after the screed has completely dried, you should lay tiles or other flooring materials that will be applied. For more information about installing a water floor in a bathhouse, watch this video:

As you can see, you can make a warm floor in a bathhouse using wood heating not difficult. As a result, the system will save money that could have been spent on purchasing a boiler and paying for electricity. By laying heating pipes under the floors, you can achieve a comfortable stay in the bathhouse, shower room and relaxation room.

For a bathhouse, a warm floor is not even a whim, but a criterion of comfort. The classic furnishings and design of the bathhouse suggest tricks to separate the floor in the bathhouse and the shelves on which a person enjoys the high temperature and steam, but any movement in the steam room will be disappointing with the cold floor underfoot. The problem is solved by many in various ways, it remains to determine how to make a heated floor in a bathhouse with your own hands in a convenient way.

The goal is to get rid of the cold on the floor surface. At least it feels like it, but it would be better to provide additional heating for the steam room. A number of solutions will allow you to cope with this. Some of them do not even involve the use of heaters or other additional heat sources other than a stove, and some have long been known for providing heating to residential premises, such as electric or water heated floors.

It's better to start with simple methods who delicately solve the problem only by selecting materials or additional insulation, and then move on to drastic methods.

Warm floor without active heating

In fact, you should only get rid of the unpleasant feeling of a cold floor, when heat is suddenly taken away from your feet and distributed over the tiles or wooden surface floor. In addition to this, it is advisable to deal with drafts and an unpleasant layer of cold air creeping along the floor surface.

It turns out that it is enough to fulfill two requirements:

- reduce the thermal conductivity of the floor;

- reduce the thermal capacity of the floor covering to a minimum.

The first task is accomplished by insulating the floor in the bathhouse using any convenient method: EPS, or polystyrene foam laid between the joists, expanded clay concrete or expanded clay backfill, etc.

The following help ensure low heat capacity of the floor covering:

- balsa wood;

- soft wood species with good drying and protection from moisture;

- natural linoleum;

- foam glass;

- keramoizol, ceramic heat-insulating material;

- soft tiles made of polymers.

Actually, apart from wood, it is unusual to see the listed materials in a bathhouse. However, they can really help to cope with the problem and fit well into the environment.

Ventilation

Another option, which is much more effective, is to use steam room ventilation to heat the floor. This is one of the options for using heat from the stove. If the bathhouse is equipped natural ventilation with good draft, for example, as part of a two-section pipe for a stove, then part of the flow of warm air from the steam room can be directed through the underground space. The situation is even simpler with forced ventilation.

The floor is laid on joists with a spacious underground space, securely isolated from the rough concrete or soil base. Additional ventilation ducts are installed from the middle of the wall to the underground space with valves. This will be the entry direction. Next, another channel connects the underground space with the chimney or ventilation pipe, always through the valve. Initially, all the above valves are tightly closed.

When the steam room is already heated, open the valves, partially closing the main hood located under the ceiling, the draft in ventilation duct sucks some of the air from under the floor, creating an additional circuit of warm air circulation. A fan will do the job faster by pumping warm air from the steam room under the floor and then out.

Electric

Most quick way provide floor heating - use electricity. However, given the high humidity and frequent wetness of the floor, maximum waterproofing of the heating elements should be performed.

The best base for an electric heated floor is a concrete screed. She is reliable protection for wire or film, and also promotes uniform heat distribution in all directions, eliminating or reducing the “zebra” effect during the operation of the heated floor.

The screed is formed with a slope in one direction or two, starting from the center of the room to drain excess liquid. The warm floor is not laid along the line of the lowest section of the floor, preventing contact of the wire with water even if damaged concrete base.

Hydrophobic and waterproofing additives and plasticizers are necessarily added to concrete, for example liquid glass or polymer fillers. It will be basic protection wires and the key to the durability and safety of floor heating. In addition to this heat reflective screen It is better to form it from a polymer film with a heat-reflecting coating and unconditional gluing of all seams. On top concrete screed it is advisable to apply thin layer additional waterproofing:

- ceramic compositions;

- bitumen containing mastics;

- polyurea;

- liquid glass.

After this, the floor covering is laid.

Water

A water heated floor is much safer than an electric one and will effectively cope with heating the floor in a bathhouse, although it will require more time. The source of hot water for heating the bath can be a stove with a built-in water circuit or a boiler general heating Houses. The choice is often determined by the location of the bathhouse itself. Naturally, there is no point in running a heat supply line from the house to the bathhouse if it is a separate building or installing an additional boiler. If the bathhouse is adjacent to the house or located inside it, then the central boiler will cope with the task much better.

A water heated floor can be installed both under a concrete screed and for heating a wooden floor with almost any type of floor covering suitable for use in a steam room.

If it is not possible to use a concrete screed, then heat-reflecting plates made of aluminum or galvanized steel are placed under the heated floor pipes, forming a groove for their laying and having sufficient large area surfaces for heat distribution.

From the stove

There is no need to use a third-party heat source when the steam room has a very efficient stove, especially since heated floors in the bathhouse are needed only when it is heated. If the furnace has a water circuit or it can be quickly installed without damage, then the natural solution would be to use a water heated floor. Count on the organization natural circulation in this case it is not necessary. The height difference is small, and even additional tricks will not increase the water flow significantly. Safer to use circulation pump, which can quickly deliver the body from the stove to the floor surface.

![]()

Guide hot air from the stove to the underground space would be a bad idea. High temperature air will dry out floorboard, moreover, not evenly causing twisting and deformation.

Under tiles

Ceramic tiles are great for heated floors. High thermal conductivity quickly transfers heat from the heating element to the surface. The tiles are laid on top of a concrete screed, so both electric and water heated floors can be used without restrictions.

The tile itself always seems cold to the touch, all because of its high conductivity and heat capacity. Even if you warm the floor to 28-30 degrees in the steam room, this may not be enough, because the air is much hotter. To bring the floor temperature to a comfortable level, you will have to heat it slightly above 35-36 oC. This imposes restrictions on the use of certain types of film electrical elements, whose temperature is strictly limited to acceptable level 28°C and for whom overheating is not desirable.

Under wooden flooring

Both severe overheating and excessive drying are harmful to a wooden floor. active ventilation. Wood itself is warm to the touch, unless it is laminated parquet or board. It is enough to raise the temperature of the underground space to a temperature of 25-26 oC to completely eliminate the problem with cold floors in the steam room.

The best solution would be water heated floors and moderate ventilation with preheated air. Electric floors are dangerous due to possible local overheating, which will cause the wood to warp. Prepared materials, such as laminate for heated floors, are rarely able to withstand the high humidity of a bath, so it is better to abandon such experiments.

The properties of warm air are such that it rises, so it may be hot in the bathhouse, but the floor will remain cold.

Such changes are uncomfortable for many people, so you can make a heated floor system, which is widespread today.

It is easier and more expedient to make a heated floor in a bathhouse from a stove than to use electric floors. After studying the material in the article, you will be able to find out the features of the system and installation methods.

General information about the system

The water in the water circuit pipes will be heated by the stove

For a heated floor in a bathhouse, there is no need to install a boiler, since the heating will come from the stove. To do this, a heat exchanger should be made from a metal tank above the firebox.

From it it will be possible to install water heating on the floor in those rooms where it is necessary. Additionally, you will need to install a pump to circulate water in the pipes.

Since it will not be possible to install a volumetric heat exchanger in the furnace, you should additionally place an accumulator tank next to it and connect it to the heat exchanger using steel pipes. To reduce heat loss, insulation is laid on the floor so that it can properly reflect it and the rooms will have the required temperature.

The main problem with a water-heated floor from a stove is the inability to regulate the temperature. For heating, it is recommended to heat the floor to 40 degrees, but in the bath the water gets hotter and you will need to additionally install a mixing unit.

To protect the floor itself from moisture, a standard cement-sand screed is used, and tiles are used as the floor covering.

Before installing the system, you need to familiarize yourself with the pros and cons, which are given in the table:

| № | Advantages | Flaws |

|---|---|---|

| 1 | There is no electromagnetic radiation, unlike the electrical system. | In winter, it is necessary to drain the water so that the pipes do not burst from frozen water or the stove must be constantly heated. The best option is to change the water to antifreeze. |

| 2 | Environmentally friendly and harmless to health. | Heating the battery tank will require a lot of heat, making the furnace less efficient for its main purpose. |

| 3 | Comfortable conditions are maintained in the bathhouse, the floor remains warm. | To heat floors in several rooms, you should install a large coolant, which will increase the warm-up time. |

| 4 | Economical. |

Warm floors can be made using several types of materials and devices, which are presented in the table:

| Name | Advantages | Flaws |

|---|---|---|

| Concrete screed is an ideal option for a bathhouse. Filling is simple and does not require special skills. | Saves money on building materials, and due to cement, the floor will be resistant to moisture. | You can use the floor a month after pouring, but if the pipe is damaged, you will have to remove the entire screed to be able to determine the location of the leak. |

| Polystyrene boards are easy to use. | Each plate already has a layer of foil, which allows it to reflect heat, and they are also equipped with places for fixing pipes. | It is necessary to additionally fill the screed. |

| Heating pipes in a wooden floor. | High maintainability. | Accurate calculations are needed to determine the laying of the pipeline. |

To insulate the system, you can use any thermal material: mineral wool, expanded clay, polystyrene foam and other types.

Floor installation and preparation

A concrete screed is poured over the laid materials and pipes

The warm floor in the bathhouse from the stove according to the scheme is made from the following layers:

- A layer of waterproofing that will protect the floor covering from condensation collection.

- The thermal insulation layer will retain the heat that can pass through the ceilings.

- To protect the insulation, a reinforcing mesh is laid.

- A layer of reflective materials with foil that will reflect heat into the room.

- A pipeline laid in the form of a spiral to uniformly heat the area.

- Screed for leveling surfaces with small slopes towards the drain hole.

- Laying the final floor covering.

If the floor will be laid on open ground, then a cushion of gravel and sand should be poured in front of the waterproofing layer, and a layer of expanded clay should also be laid. Expanded clay will additionally perform a thermal insulation function.

Before any work, preparation is necessary. For a floor that will be heated by a stove, you should prepare a base and make a drain. The work is carried out as follows:

- It is necessary to remove the soil between the foundation, under the washing room and compact the surface. You will need to first lay a pipe in the wall to drain water into the sewer.

- A backfill of sand and gravel 15-20 cm high is made, after which the cushion is compacted.

- The base is insulated using expanded clay. The layer of material is 15-20 cm depending on the climate.

When preparing the surface, you need to remember the slope for the drainage.

Step-by-step installation instructions

Heating the floor in the bathhouse using the heat of the stove is a profitable step

The base of the bathhouse is ready, which means it’s time to start laying out the pipes. For this you can use both copper pipes and metal-plastic ones. The installation process is as follows:

- Initially, waterproofing material is installed. For this, roofing material is used, which is laid in two layers. Its joints are glued together with mastic, and all strips of material must be perpendicular to each other.

- Next, thermal insulation is laid.

- The next step is to lay the reinforcing mesh, which will protect the insulating materials.

- Pipes for floor heating are placed on top of the grid and connected to check their functionality and the presence of possible leaks.

- When all the materials are laid, you can begin to pour the screed over the entire area of the room. A damper tape is first glued around the perimeter of the rooms, which will prevent the floor from deforming due to temperature. Any type of mixture can be used for screeding.

- The floor filling is leveled along the beacons and the angle to the drain is maintained.

- The water-heated floor is almost ready; after the screed has completely dried, tiles or other floor materials that will be used should be laid. For more information about installing a water floor in a bathhouse, watch this video:

As you can see, it is not difficult to make a warm floor in a bathhouse using wood heating. As a result, the system will save money that could have been spent on purchasing a boiler and paying for electricity. By laying heating pipes under the floors, you can achieve a comfortable stay in the bathhouse, shower room and relaxation room.

.JPG)