Interesting and useful homemade crafts for the home. Homemade tools for the garage, for storing tools in the garage. Homemade devices for the home workshop Tricky mechanisms with your own hands

The master is not distinguished by greed, which some masters suffer from, who do not want to share their finds with others and, like a dog in the manger, neither to themselves nor to people. And this self-taught inventor came up with a great device with which you will always be at your best and can even improve your standard of living. Why, you can put such a tool into production and sell it to everyone. Maybe this is too strong a word, but it’s worth thinking about automating and mechanizing all routine work at home.

8 tools for craftsmen.

You probably haven't seen many of them. Cool instruments are created by DIYers. These devices will help you work more comfortably in the workshop. The video was filmed on the “Hands from Shoulders” channel.

Folding table for the master

1. Let's start with a folding table, which will be an excellent assistant in a small workshop. It will help save an already small area. The table has a compartment for all small things. A shelf on which you can lay out the necessary tools. Thanks to the large number of holes, a clamp can be used to quickly and conveniently fix the workpieces. Stops are inserted into them. It is convenient to fix the parts in a vertical position. If we insert it into the guide bolts, we get additional stops. Having a set of clamps and such a table, you can comfortably perform a variety of jobs.

Homemade folding stand

2. Very original idea folding stand for hand tools. Everyone is in their place. It doesn't take up much space. The design is based on furniture guides. The stand is held in the upper position. Neodymium magnets prevent instruments from falling out of their stocks. Great idea for DIYers who love to do everything with their own hands.

Apple puller

3.Gardeners will be interested in the fruit puller. Its advantage over analogues is that it is absolutely free and easy to manufacture. Not hard to find at all plastic bottle, rope and cut the stick. 5 minutes and you can go for apples.

Homemade apple press

4. If the harvest is large, then the question arises, where to put it? A great option is apple juice. For store-bought juicers, apples need to be cut and peeled, which is inconvenient. The grater shown below can handle whole apples. All that remains for Dali is to squeeze out the resulting mass under pressure. As a result, we get natural, tasty juice and almost dry cake.

Tool trolley

5. The mobile tool cart is very convenient for the workshop. When, for example, the workbench is littered with parts. Or it doesn't exist at all. By loading everything you need at the moment into it, you get the entire tool in one place at hand.

What can you make from an electric planer with your own hands?

6. Another one interesting design surface planer - based on an electric planer. With the help of guides it moves in 2 planes. The movement takes place using an elevator. For precise adjustment, there are rulers on each side of the device.

Grinding device

7. Having a jigsaw, you can get a cool sanding tool. Interestingly, it is not the abrasive that moves, but the workpiece itself.

Cheap homemade grinder

8. The most budget version of the grinder, created by the Samodelkins. Plastic bottles are used as rollers. They are mounted on bearings. The belt on the rollers is adjusted using thumbwheels. The tension is adjusted with a bolt. The structure is driven by a drill. You can slightly improve Samodelkin’s design by replacing plastic bottles with polypropylene tubes.

The self-taught self-made man rocked the network with his video

The self-taught inventor captivated the online community of craftsmen with his video, in which he presented a fundamentally new utility model for improving the efficiency of work for craftsmen and those who like to work in the garage. The best part is that it doesn't require you to buy an idea. And what’s more, you can do all this yourself and even a novice master can handle it. All this is to the benefit of every resident of the cities in which the masters settled, because with such high level mastery, now you won’t want to hammer the walls at home on weekends or rattle some ultra-decibel grinder unknown purpose. With such a device, you can safely create your own separate workshop and live rich life Russian artisan.

Homemade tool rocks the internet

This video shook up the community of invention lovers on the world wide web. The master thought about this idea for years and finally brought it to public discussion, brilliant in its simplicity and radically profitable idea for those who used to hammer walls with a hammer drill, I am realizing my inclinations as a woodpecker and a brilliant builder-grinder, and now can make myself a rich man completely free of charge, working in the quiet of a workshop in a garage or even in a separate building.

And at the same time, you don’t have to spend money and take money saved for beer out of your stash. All this is free - the master loves to show the whole world the useful things he comes up with.

Uprooting of seedlings and weeds from a square for homemade people

Good afternoon My long absence from the channel was not in vain; during this time I managed to do a lot of household chores. And of course, I stocked up on a bunch of homemade products that I will show you, my dear subscribers and guests! There is no point in posting everything at once, because this also takes a lot of time, but if possible I will try to post at least one per day. Not only am I sitting at the computer, I can’t leave my workshop. Messing around in the garden is another hobby of mine; I spent a lot of time there in the summer. Caring for plants and weeding, although a pleasant activity, however, also requires a lot of effort. And how I would like to make a lot easier. Wanting alone is not enough, so you need to make useful things yourself that will make your work easier and make it a pleasure, rather than hard labor with a farmhand.

Today I’ll show you a device that I successfully used almost all spring and summer and will, God willing, last for more than one season. Do-it-yourself uprooter To make it, I took a square with walls 40 by 40 mm, length 220 mm. I didn’t cut this length on purpose, I had a lot of such scraps left over from others construction work.  I drew two oblique lines along the walls to the corner of the square. Having cut it out, it turned out to be such a spear. In inner part welded a pipe with a diameter of 25 mm using an angle. From the outside I welded a square right in the middle of the square. Instead of a square, you can weld a square, but it seemed to me that it would be more convenient.

I drew two oblique lines along the walls to the corner of the square. Having cut it out, it turned out to be such a spear. In inner part welded a pipe with a diameter of 25 mm using an angle. From the outside I welded a square right in the middle of the square. Instead of a square, you can weld a square, but it seemed to me that it would be more convenient.  A metal handle was installed in the pipe so that it would not break under load, because the force falls mainly on the handle. When working with a flat cutter, some types of weeds still germinate after a certain time, especially after rains. And having ripped it out by the roots, I eliminated this possibility and my garden became well-groomed and beautiful. Without damaging the root system, they can also remove seedlings for replanting, which is what I did at the beginning of the season with strawberries and other plants.

A metal handle was installed in the pipe so that it would not break under load, because the force falls mainly on the handle. When working with a flat cutter, some types of weeds still germinate after a certain time, especially after rains. And having ripped it out by the roots, I eliminated this possibility and my garden became well-groomed and beautiful. Without damaging the root system, they can also remove seedlings for replanting, which is what I did at the beginning of the season with strawberries and other plants.

A simple cheap homemade device for picking berries

Gooseberries are a tasty and healthy berry. The plant itself is quite unpretentious and does not require any special care. The berries grow large and are quite convenient to pick. And everything would be fine if it weren’t for the prickly gooseberry branches. Because of these garden “cacti,” my hands used to constantly have small scratches. And several times you will think “do you need it - there are so many berries” before you climb deep into the bush for the harvest. But a few years ago my husband made my life easier. He spotted one very simple but useful device for picking berries on the Internet. What is it used for and how is it useful?

In fact, such a picker can be used not only for collecting gooseberries. I also use it to pick any other berries/fruits. hard to reach places oh, where you can’t easily reach with your hand. For example, to remove plums, cherries or apples from high branches. How to make a device for picking gooseberries? Everything ingenious is simple! Take a plastic bottle and cut a droplet-shaped hole on the side. Depending on what berries/fruits your picker is intended for, this is the diameter of the drop. For gooseberries, 5-7 cm is enough, for apples and plums more, so that you don’t have to aim for a long time and try to hit the fruit. The volume of the bottle will also depend on what you are collecting. For berries, a 0.5 liter bottle is better.

The droplet's nose should be directed toward the bottom of the bottle. You can also make a cut a couple of centimeters in continuation of the spout so that the branch can be better grasped. That's it, our device is ready! We will pick berries by holding it by the neck.

It really is much easier to do this with him. Not only do your hands remain scratch-free, but the work also goes faster. After all harvested will be poured into top part bottles. Accordingly, there is no need to “climb out” from the bush after each berry, put the harvest in a can or jar and climb again. Plus, we can get berries even from the most inaccessible places. And the most important thing is that such a device is made in 3 minutes, does not cost a penny, and makes life much easier. If it gets lost or gets dirty, no problem – we’ll do another one without any problems! So, gardeners, take action! If the article was useful to you, give it a “thumbs up” and subscribe to the channel for summer residents and gardeners “SADOёZH”.

Currently, you can purchase ready-made machines to equip your own workshop, but all this will be quite expensive. Homemade machines will help the master in his practical work , and will not burden his budget. Why buy something that you can do yourself, and even in relation to specific conditions.

Each owner chooses the equipment of his own workshop himself. It depends on the hobby, i.e. type of work and area of the premises. Minimum area of a home workshop in which it makes sense to place equipment is 3-4 m².

It can be located in a small room or on the balcony of an apartment, a separate building on its own site or in a garage. Perfect option- This is a secluded room in which you can make noise without disturbing other people.

According to its purpose, a home workshop can be universal, i.e. to carry out any work that unexpectedly arises in everyday life, or have a specific direction, associated with the master’s hobby. Most often, workshops are equipped for working with wood, i.e. For carpentry work. Quite often there is a need for metal processing ( locksmith work) And car repair.

In general, setting up a home workshop includes the following elements:

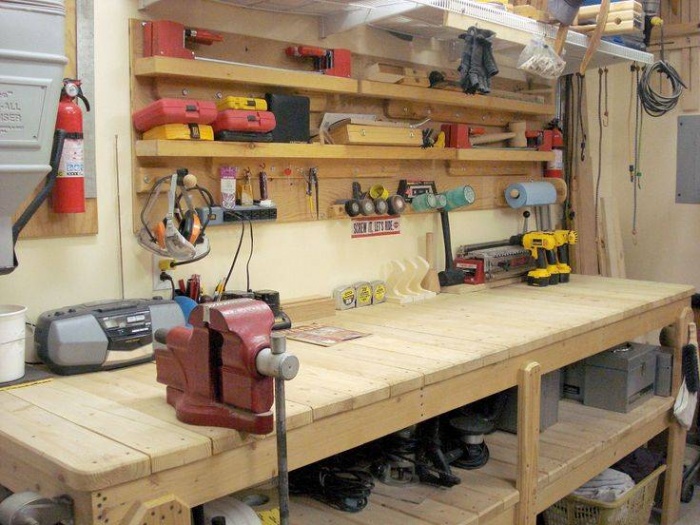

- structures for storing tools and materials (racks, shelves, cabinets);

- equipment for work (workbenches, work tables);

- machines for processing materials;

- devices for mechanizing work, facilitating labor, preparing tools, etc.

The equipment must be placed so that there is access to it free approach, was observed safety and fire regulations, provided minimal comfort.

Shelves for tools and materials

Setting up your home workshop begins from installing practical shelves for a DIY tool. They can be made of metal or wood, or have a combined design - a metal frame with shelves made of wood, plywood, chipboard, plastic, etc.

The following stand out basic structures:

- Racks in the form of a frame and shelves located at different heights.

- Shelves mounted on the wall. They can be installed on brackets or attached with dowels directly to the wall surface.

- Hanging shelves with ceiling mounting.

Practical shelf-boards have this design. The basis is a shield cut from plywood 8-12 mm thick.

Practical shelf-boards have this design. The basis is a shield cut from plywood 8-12 mm thick.

There are 3 types of fasteners mounted on it:

- a rail with slots for placing tools with a handle in a vertical position (hammer, screwdrivers, chisels, etc.);

- shelves with a side for placing boxes with small tools (drills, taps, dies, etc.);

- hanging hooks small tool(knife, scissors, measuring tool, etc.).

This shelf-shield is fixed to the wall using dowels.

Carpentry workbench

A carpenter's workbench is a durable table with a working surface on which to fix holdfast(2 pieces), clamps to secure the workpiece when planing with a plane, there are places for installation milling cutter and other manual machines.

Important. The dimensions of the workbench are selected based on practical considerations.

The height should ensure ease of work, taking into account the actual height of the master. The length should be at least 1 m (usually 1.7-2 m), and width - 70-80 cm.

Instructions for making a carpentry workbench:

- The working surface is made in the form of a shield with tightly fitted boards with a thickness of at least 55 mm. Beech, oak, and hornbeam are best suited. They should first be soaked in drying oil. Strengthening is achieved with a beam measuring 4-5 cm, which is attached along the entire perimeter of the shield.

- Vertical table supports can be made of pine or linden. Typically, a beam measuring 12x12 or 15x15 cm with a length of about 120-135 cm is used. The supporting elements are connected by horizontal jumpers made of a wide board, fixed at a height of 20-30 cm from the floor.

- Tools and accessories are stored on shelves that are located under the lid. It is better to make them in the form of a cabinet with a door. Shelf panels can be placed on the wall above the workbench.

- A pair of homemade or factory-made carpentry vices is attached to the working surface.

Reference. The workbench can be mobile (movable), folding (collapsible) or stationary. In the latter case, it is recommended to bury the supports into the ground by 15-20 cm.

Vise

For a homemade vice you will need a long screw rod with a diameter of at least 20 mm with a threaded part length of at least 14-16 cm, metal studs and wooden blocks.

For a homemade vice you will need a long screw rod with a diameter of at least 20 mm with a threaded part length of at least 14-16 cm, metal studs and wooden blocks.

Manufacturing is carried out in the following order:

- A wooden block is cut out (possibly from pine) about 20x30 cm in size and at least 5 cm thick, in which a hole for a screw is drilled in the center, and at the bottom there are 2 holes for guide pins. This first vise jaw is permanently fixed to the work surface.

- The second sponge is cut from a similar board and has dimensions of 20x18 cm. This will be a movable element.

- A screw pin is passed through the jaws. To prevent displacement of elements, studs with a diameter of about 8-10 mm are fixed. A handle is installed on the screw rod.

How to make a metal workbench with your own hands?

To carry out plumbing work you will need a metal workbench. Its standard size: length 1.8-2.1 m, width – 0.7-0.8 m, height – 0.9-1.2 m. Manufacturing includes the following steps:

- Assembling the workbench frame with imparting longitudinal rigidity.

- Assembling and securing 2 cabinets in the form of a frame covered with a metal sheet.

- Installing the work surface – wooden shield, sheathed on top with a metal sheet.

- Installation of a tool rack, which is attached to the back of the workbench and further strengthens it.

- rack beams - profile pipe with a wall of at least 2 mm, size 4x6 cm. Needed - 4 pcs.;

- beams measuring 5x4 cm for horizontal linking of posts, providing longitudinal rigidity. Quantity – 3 pcs.;

- profiled pipe (9 pcs) for making a frame for cabinets measuring about 4x3 cm with a wall thickness of at least 1 mm;

- a 5x5 cm corner for vertical rack posts with a height of 1.5-2 m. For horizontal linking, you can use a 4x4 cm corner;

- board for the tabletop with a thickness of at least 5 cm;

- a metal sheet for a working surface with a thickness of at least 6-8 mm.

Features of creating a wood lathe

A homemade lathe for working with wooden blanks includes the following elements:

- bed. It must have sufficient strength. It is better to make it from a metal profile (pipe, corner), but it can also be made from wooden beam. It is important to securely fasten the frame to the workshop floor and weight the structure at the bottom.

- Headstock or clamping spindle. As this element of the machine, you can use a head from a high-power drill.

- Tailstock. In order to ensure longitudinal feed of the workpiece, it is better to use a standard factory spindle with 3-4 cams.

- Support or stop for cutters. It must provide reliable fastening and the ability to move towards the workpiece, which is ensured by a screw rod.

- Tool table. A working surface should be formed on the bed on which cutters and other tools can be laid out.

- Drive unit. To create torque, an electric motor with a rotation speed of 1500 rpm and a power of 250-400 W is used. You can use the engine from washing machine. A belt drive is used as a transmission, for which pulleys are installed on the shafts the right size.

Incisors

Even in a homemade lathe it is better to use factory cutters, which will provide increased quality. However, if you wish, you can do this on your own. Homemade cutters wood can be made from the following materials:

- Steel reinforcement. The best option is a square section with a size close to the size of the factory tool.

- Files. A worn tool is selected, but without significant defects.

- car spring rectangular (square) section.

Prepared cutter blanks are sharpened. For roughing work, a semicircular cutting edge is used, and for finishing work, a cutter with a straight blade is needed. In addition, shaped and through cutters with specific sharpening may be required. Next, the cutting part requires hardening. To do this, it is heated and then lowered into engine oil.

Instructions for creating a stationary circular saw

The most important element of a stationary circular saw is reliable table with work surface. The most suitable for it is a metal sheet reinforced with stiffening ribs from a steel angle. The following parts are located on the worktop: cutting disc, guides, thrust and control elements.

Drive is provided electric motor power of about 0.8 kW with a minimum speed of 1700 rpm. Transmission – belt drive.

Drive is provided electric motor power of about 0.8 kW with a minimum speed of 1700 rpm. Transmission – belt drive.

Make circular saw Can from the grinder in the following order:

- Installation of the frame and production of the working surface. Cutting a space to install the disk.

- Consolidation parallel stops from wooden beams.

- Installing a scale to adjust the cutting process.

- Installation of clamps for fixing guides and workpieces.

- Fastening the grinder from the bottom of the table top with the disk directed into the slot.

Assembling a homemade drilling machine

The procedure for assembling a homemade one drilling machine shown in the video below. It is based on an electric drill, which is mounted on a frame with the possibility of vertical movement.

Main elements of the machine:

- Electric drill.

- Metal base with clamps for workpieces (clamps).

- Stand for attaching a drill. It can be made from chipboard 2-2.5 cm thick. A good option- base from an old photographic enlarger.

- Feed mechanism cutting tool. Guide rails are installed on the stand to ensure strictly vertical movement of the drill. The easiest way to feed a tool is manual lever and springs. Adjustable stops are installed to control the depth.

CNC milling machines for wood and metal

When milling wooden parts software allows you to significantly expand the capabilities of the machine and the quality of processing. To form it, elements such as LPT port and CNC unit. To make a copy unit, you can use the carriages of an old dot matrix printer.

Assembling the wood router is carried out in the following order:

- The tabletop is made of chipboard or plywood with a thickness of at least 15 mm.

- A cutout is made for the cutter and its installation.

- The drive, transmission and spindle of the machine are secured.

- Stops and limiters are installed.

Assembling a metal router requires more solid foundation

for the machine:

Assembling a metal router requires more solid foundation

for the machine:

- Installation of a column and frame in the shape of the letter “P”. The elements are made from steel channel. In a U-shaped design, the bridge is formed by the base of the instrument itself.

- The guide elements are made from angle steel and are bolted to the column.

- The guide consoles are made of a rectangular pipe. A screw pin is inserted into them. The movement of the console is ensured using a car jack to a height of 12-15 cm.

- The worktop is made of chipboard or plywood.

- A vice with guides from metal corner, pin clamps.

- The rotating part is installed so that the shaft is vertical.

Thicknesser

A homemade thicknessing machine for wood includes the following elements:

- bed. It is made of 2 frames welded from a corner 40x40 or 50x50 mm. The frames are connected with studs.

- Broach. Rubber squeezing rollers from a washing machine work well. They are mounted on bearings and rotated manually using a handle.

- Working surface, table top. A wide board impregnated with drying oil is used, which is secured to the frame with bolts.

- Drive unit. You need a three-phase electric motor with a power of 5-6 kW with a rotation speed of at least 3000 rpm.

- casing. To protect the rotating parts, a casing is installed steel sheet 4-5 mm thick, mounted on a frame made of steel angle 20x20 mm.

note

Can be used as a working body electric planer.

It is fixed with clamps on the working surface to form the required gap. This gap must be adjusted using shims and set taking into account the thickness of the workpiece.

Creating a wood sanding machine

A homemade grinding machine has drum design, i.e. a rotating cylinder with a emery cloth. It can be produced in the following varieties:

- surface grinding type that provides grinding in only one plane;

- planetary a type capable of processing a part in different directions, creating an even plane on it;

- cylindrical grinding type for processing cylindrical workpieces.

When securing the abrasive cloth, the following recommendations should be taken into account:

- The width of the tape is about 20-25 cm.

- The strips are connected end-to-end, without a gap.

- To strengthen the joint seam, a thick tape is placed under it.

- Only high quality glue should be used.

- The shaft for the sanding strip has a side at the edges that protrudes by 2.5-4 mm.

- It is recommended to use thin rubber (for example, a bicycle inner tube) as a backing for the abrasive element.

Rules for operating a wood jointer

A homemade jointing machine will help when repairing furniture and apartments. When using it, the following rules should be observed:

- The jointer is adjusted in such a way that the maximum errors are ensured - vertically (perpendicular) - no more than 0.11 mm for every 1 cm; in plane - no more than 0.16 mm for every 1 m.

- When processing workpieces smaller than 3.5x35 cm, pushers should be used to hold them.

- Wear of the cutting element is indicated by scorching and moss on the surface of the part.

- An uneven surface after machining indicates an inaccurate positioning of the cutting edges.

Homemade garage gadgets

In a home workshop equipped in a garage, you can repair your car yourself. In particular, the following homemade devices and machines are of interest.

Hydraulic jack press

He will help when removing and crimping silent blocks car. With its help, a load of several hundred kg is provided.

He will help when removing and crimping silent blocks car. With its help, a load of several hundred kg is provided.

The structure consists of a frame and a hydraulic jack. The frame is welded from a high-strength rectangular pipe.

After lifting the car, it becomes a stationary, reliable support for the car.

This allows you to safely press out the jammed part using internal clips from the bearing.

Ball joint remover

It can be made in different ways:

- Lever type. These are 2 levers connected in the center. On one side, a coupling bolt is installed on them. When acting on the support, it unscrews, bringing the ends of the levers closer together. In this case, one end is inserted between the support and the eye, the second - under the finger.

- Option "wedge". A wedge-shaped workpiece is cut from a metal plate. From the outside top corner a strictly vertical cut is made at 70% of the height. This wedge is installed between the ball joint and the eye. Then it is hammered in until the finger comes out of the socket.

It's nice to see when a person made everything and other household items with my own hands. To simplify the process of cutting metal or sawing elements from wood, they build homemade machines and devices for the home workshop. This solution saves not only time on manufacturing products, but also money on purchasing ready-made ones. Let's look at a few practical and interesting options below.

DIY pipe bending machine

Read in the article

How to use homemade machines and tools for your home workshop

The use of homemade machines and devices for the home workshop is aimed at solving several problems:

- Simplifying the metal processing process. When creating household items, a metal cutter or press is often required.

- Improving wood processing. Even to build a small shed or make a wooden one, others are needed.

Buying a ready-made tool is quite expensive, so the use of homemade machines and devices for the garage is becoming more and more relevant every day. Among the most common options for home tools are:

- carpentry workbench;

- device for quickly sharpening knives;

- device for sharpening metal drills;

- drilling machines;

- press;

- cutting disc machines.

Here are a few photos of do-it-yourself tools and devices from “homemade” people:

1 of 4

Practical DIY tool shelves

Before creating devices and with your own hands, determine the storage location of all devices, so that later you do not have to search throughout the workshop or where everything is. It’s not difficult to make a shelf for tools with your own hands; the main thing is to decide on its dimensions and material of manufacture.

The easiest way to make shelves is to assemble them from wood. Do not forget about the need to coat the finished structure with a protective varnish or to prevent rotting and swelling of the wood.

You can create combined option from a metal support and wooden shelves. Here detailed instructions to create such a homemade model:

| Image | Sequencing |

| Assembling the frame. To do this, prepare two side frames consisting of 4 corners. Connect the elements using . Then, tighten the 2 frames together using 4 corners. |

| When the frame is completely assembled, proceed to making the shelves. They can be made from wood or metal, as well as from other dense materials at hand. It is enough to cut the canvases of a suitable size and attach them to a metal base. |

| If desired, you can make the rack movable by attaching four small wheels. Or install it firmly in a designated space in the garage. |

You can find others interesting projects and drawings for making tool shelves. Watch the video on the topic:

And also make useful household gadgets with your own hands:

1 of 4

We make a carpentry workbench with our own hands according to the drawings: video instructions and photo examples

Among the common do-it-yourself devices is a workbench. Durable and dimensional, allowing you to securely fasten the workpiece, useful for high-quality cutting of wood and creating from it various elements.

The device package includes:

- Working surface. Hard is used for it to increase the service life of the device. The thickness must be at least 6 cm.

- Supports. Assembled from wooden beams or metal plates. The main task is to ensure the stability of the entire mechanism.

- Vise for securing the product. If the table is long, you can install two vices at once.

- Tool box. Useful recess or retractable design, providing quick access to necessary small parts.

To assemble a carpentry workbench for your workshop yourself, you should choose a drawing and purchase materials for the work.

DIY carpentry workbench drawings

Before purchasing materials to assemble your own workbench, you should think about a detailed drawing. It should include the dimensions of the machine itself; it is advisable to note the dimensions of the materials used and their quantity.

For example, finished drawing A DIY folding workbench may look like this:

Whatever model you choose to create, take into account several features of the workbench that ensure ease of cutting wood:

- height and length of the master’s arms: the height and width of the tabletop depend on these parameters;

- which hand is working: place the vice on the right or left;

- what blanks will be made: choosing the shape of the table;

- how much space in the room do you allocate for the workbench?

Taking into account all these parameters, it will be easier for you to decide on the drawings of the carpentry workbench and the dimensions of the machine. Here are some interesting examples:

Instructions for assembling a wooden workbench with your own hands

You can buy a wooden workbench in a store or through online catalogs, but it’s cheaper to make it yourself. Let's take as a basis a simple option with standard sizes tabletops: length – 150-200 cm, width 70-120 cm.

The manufacturing work will include several stages:

| Image | What need to do |

| Make the top cover from thick ones to make a shield with a width of 70 to 200 cm. Fasten the elements with long nails, and you need to drive them in from the outside and carefully bend them from the inside. The working surface of the workbench is made only of wood or. |

| Sheathe the lid along the lower perimeter with a 5 by 5 cm beam. This will make it more convenient to attach the vertical supports. The location of the supports depends on the size of the tabletop. It is better to make them from thick rectangular timber at least 120 by 120 mm. |

| The carpentry workbench must be installed correctly. Be sure to secure it firmly. If it will be mounted outdoors under a canopy, dig holes for supports. Indoors, use other fastening methods. |

When the structure is assembled, install a vice on it. To fully understand how to assemble a carpentry workbench with your own hands, watch the video:

Making a carpenter's vice for a workbench with your own hands

Professional “homemade workers” assemble not only tables for work, but also vices with their own hands according to drawings. Any design of such a clamp will include several elements:

- Supports, where each one has a sponge for clamping.

- Moving jaw.

- Metal guides. The sponge moves over them.

- Lead screw for moving elements.

- Collar. Necessary for rotating the screw.

When making a homemade vice with your own hands, you can use various available materials. For example, there is a design option from profile pipe. To do this, prepare several pieces of pipe of different sizes, a steel stud with large threads and double nuts.

Instructions for creating a bench vise from a profile pipe:

| Image | What need to do |

| The largest pipe acts as a body. Supports are soldered to it from below. A 3-4 mm steel flange is put on the back side. A hole is drilled in the center for the running nut, and opposite the front support is the rear jaw. |

| There is a front steel flange on the internal moving part. A stud is mounted in it, with lock nuts attached to it. Thrust washers are placed on both sides of the flange. The last element is a movable tube attached to the front jaw. |

And also watch the video “do-it-yourself vice at home”:

DIY metal workbench drawings

A metal workbench does not differ much from a carpenter's workbench. The base is hard metal, not wooden frame. A vice is attached to it, and the entire workbench is designed to withstand the force of a sledgehammer.

Do-it-yourself metal workbenches can have one, two or three cabinets, and also not have shelves or drawers for small parts. In terms of strength for working in a garage, you can make a regular table made of metal up to 5 mm thick and a reinforced structure where sheets from 10 to 30 mm are applicable.

Here are some useful plans for making a metal workbench for your workshop:

How to make a device for sharpening knives with your own hands: drawings and photo examples

No home is complete without a knife in the kitchen. It is quite difficult to make the correct one without special devices: you need to maintain the desired angle and achieve the ideal sharpness of the blade.

For each knife, a certain sharpening angle must be observed:

- A razor and scalpel require an angle of 10-15⁰.

- Knife for cutting bakery products – 15-20⁰.

- Classic multifunctional knives – 25-30⁰.

- For hunting and hiking, take a device with a blade angle from 25 to 30⁰.

- If you want to cut hard materials, then sharpen at an angle of 30-40⁰.

To ensure the desired angle, it is worth buying or making a sharpening device. For example, you can assemble a sharpener with your own hands.

A comment

Tool selection specialist at VseInstruments.ru

Ask a Question“If you don’t use sharpening every day, then 1000 rpm is enough for a high-quality result and long term operation of the device.

"To assemble such a machine, you will need a motor from a washing machine with a power of 200 W. Completely for creating a sharpener from an engine from the Progress of work on creating such simple device will be as follows:

- Sand the wood blocks with sandpaper, removing any burrs. Make markings depending on the desired angle.

- Attach a stone to the drawn line to give the blade a sharp edge. To do this, attach it to the block and mark its width. Then, make cuts on the markings, up to 1.5 cm deep.

- Attach abrasive stones to the resulting recesses so that the grooves coincide. Then, install the sharpening stone by screwing it onto the bolts.

There are many ways to make a homemade knife sharpener. Choose the one that suits you and try to create a convenient and useful tool for your home.

How to make a device for sharpening a metal drill with your own hands

They make their own not only a sharpener for blades, but also a machine for sharpening drills for metal. Here are a few drawings useful for work:

Ready home machine The simplest and most common version of such equipment for a garage is a converted drill. To work you will need:

Ready home machine The simplest and most common version of such equipment for a garage is a converted drill. To work you will need: - base frame;

- rotation mechanism;

- vertical stand.

For the rack, they usually use either boards. The drill is lightweight, so there is no need to use metal. In this case, the frame must be made massive in order to reduce vibrations during operation of the device.

To properly connect the frame and vertical stand, and also assemble all the equipment into one whole machine, pay attention to the video instructions:

DIY drawings with dimensions for a drilling machine

To correctly make any machine or practical device for private use, you should first make a drawing with dimensions. Only then begin preparing materials and assembling the device.

Here are some examples of do-it-yourself drilling machine drawings from a drill:

You can also do homemade vice for drilling machine. Below is a video instruction for assembling such a device:

Article

Many car owners use their garage as a workshop, gradually filling it with practical devices that make car repair and maintenance easier. Many of them can be made independently using the recommendations presented in this article.

Many accessories for a garage workshop can be made independently; the video below demonstrates some of them.

Garage homemade products are devices that make garage life much easier; in addition, they work no worse than factory machines. By equipping your workshop with such devices, you can independently produce the necessary parts for your car, as well as various crafts for home or cottage.

Video of homemade tools and accessories for the garage

It is difficult to predict in advance what devices may be needed when repairing a car, however, there are some homemade products, some of which are used most often. Some of them can be seen in the video below.

Drawings of homemade devices

Pipe bender - useful in household a device that allows you to bend metal or polymer pipe at a certain degree. Bent pipes often used in the construction of greenhouses and greenhouses, installation of heating and other needs. Using the presented drawing, you can make a manual pipe bender yourself.

A vice is a practical device used when performing plumbing work. With its help, it is possible to reliably fix a part requiring metalworking in a certain position.

Consists of this device from several parts:

- base plate;

- 2nd lips – movable and non-movable;

- lever;

- chassis screw.

Using a small-sized bench vice, the drawing of which is presented above, it is convenient to sharpen and otherwise process small parts.

Having a CNC milling machine in your home workshop allows you to perform a whole range of work on machining tree.

Homemade milling machine consists of several units and parts:

- bed;

- calipers designed to move cutters;

- caliper guides;

- spindle with installed cutter;

- microcontroller or switching board with microcircuits that provide automation of the machine;

- electric motor with power supply;

- drivers responsible for transmitting commands from the controller to the electric motor;

- a vacuum cleaner for collecting sawdust generated as a result of the operation of the machine.

A DIY CNC milling machine allows you to perform engraving and milling work.

Homemade tools for car repairs

Windshield wiper arm remover – special tool, facilitating the process of removing the wiper arms. You can make it yourself from a piece of reinforcement, a six-channel channel and a ten-bolt. To do this, use a drilling machine to make 14 holes and weld 2 nuts on both sides of the hole and a handle from the reinforcement, screw the bolt into the workpiece and, putting on heat shrink, screw in the threaded rivet. The tool is ready.

Windshield wiper arm remover – special tool, facilitating the process of removing the wiper arms. You can make it yourself from a piece of reinforcement, a six-channel channel and a ten-bolt. To do this, use a drilling machine to make 14 holes and weld 2 nuts on both sides of the hole and a handle from the reinforcement, screw the bolt into the workpiece and, putting on heat shrink, screw in the threaded rivet. The tool is ready.

Another version of the device for shooting windshield wiper arms is shown in the photo below.

Another useful homemade device with which you can manually re-align your wheels yourself. Another version of this device can be seen in the photo below.

Another useful homemade device with which you can manually re-align your wheels yourself. Another version of this device can be seen in the photo below.

When carrying out major car repairs, you usually cannot do without a lift. A device made in a factory is not cheap, and is not needed very often, so it can easily be replaced with a device made at home.

When carrying out major car repairs, you usually cannot do without a lift. A device made in a factory is not cheap, and is not needed very often, so it can easily be replaced with a device made at home.

Homemade machines and devices for the garage

By making devices for mounting and balancing tires, you can carry out this work yourself, significantly saving money on car maintenance. In addition, such devices will come to the rescue if it is not possible to come to a specialized tire shop.

In your garage workshop you can equip universal machine for tire fitting using scrap materials - metal pipes and the hub.

In your garage workshop you can equip universal machine for tire fitting using scrap materials - metal pipes and the hub.

When performing various crafts for the home, it often becomes necessary to drill a straight hole. This is difficult to do with a regular drill, but if you make a stand for the drill, like the one shown in the photo, then drilling without distortions will be much easier. This design can be made from various materials. For example:

When performing various crafts for the home, it often becomes necessary to drill a straight hole. This is difficult to do with a regular drill, but if you make a stand for the drill, like the one shown in the photo, then drilling without distortions will be much easier. This design can be made from various materials. For example:

- made of metal;

- made of wood.

Using the diagram presented below, you can make your own drilling machine from a drill.

Usage homemade press will allow the garage workshop to produce products using the pressing method. A similar device can be made from a hydraulic jack fixed to the top of the frame, which in turn is welded from scrap materials. The pressure in this case is directed downward.

Another version of a homemade press, the design of which involves attaching a jack at the base of the bed. In this case, the pressure process is carried out upward.

Using a homemade press, you can straighten, bend sheets of metal, compress cardboard, and fasten individual elements. The video below demonstrates how to make such a necessary device yourself.

Tool storage devices in the garage

Having order is the key to comfortable use of workplaces in the garage. To ensure this order in the workplace, special organizers are designed to make it convenient to store and easy to find. necessary tools. You can make such devices yourself, using available tools.

Simple and in an accessible way storing hand tools is wall organizer made from tin cans attached to a plywood sheet. Additionally, you can nail several hooks or nails to it to conveniently hang the measuring and electric tool. In the absence of tin cans, PVC pipes of various diameters can be used as holders, cut into pieces and screwed to a sheet of plywood or chipboard.

Simple and in an accessible way storing hand tools is wall organizer made from tin cans attached to a plywood sheet. Additionally, you can nail several hooks or nails to it to conveniently hang the measuring and electric tool. In the absence of tin cans, PVC pipes of various diameters can be used as holders, cut into pieces and screwed to a sheet of plywood or chipboard.

It’s even easier to make a special device for storing screwdrivers. To do this, you need to take a wooden block and drill holes of the required size in it. Mount the finished holder on the wall. On the same holder you can organize a storage system for chisels and chisels. It is enough to cut out special holes in a wooden blank. In the same way, you can make a holder for power tools by cutting out the corresponding holes in a wooden shelf.

It’s even easier to make a special device for storing screwdrivers. To do this, you need to take a wooden block and drill holes of the required size in it. Mount the finished holder on the wall. On the same holder you can organize a storage system for chisels and chisels. It is enough to cut out special holes in a wooden blank. In the same way, you can make a holder for power tools by cutting out the corresponding holes in a wooden shelf.

Interesting way Tool storage is suggested in the photo above. Its principle is based on the use of magnetic tapes attached to metal strips. Using such a system, it is convenient to store drills, keys and other metal tools.

Interesting way Tool storage is suggested in the photo above. Its principle is based on the use of magnetic tapes attached to metal strips. Using such a system, it is convenient to store drills, keys and other metal tools.

Convenient and practical organizers for storing screws, bolts, nails and other small items can be made with your own hands from transparent plastic jars with lids. To prevent them from taking up space, you should attach them by the cover from below to the shelf. This and other ways to store tools allow you to efficiently use space in the garage and have everything you need at hand.

The video below demonstrates how to set up a simple and convenient system storage of tools.

Homemade woodworking tools for the home workshop

Homemade milling machines can perform one or more operations. Preference, of course, is given to multifunctional devices that save space in the garage workshop. With their help you can:

make indentations of a certain shape;

drill holes

make grooves;

process the workpieces.

The simplest milling machine can be made on the basis of a drill. To do this, it is fixed to a steel profile or to a plywood body, and a rotating clamp is placed opposite it. Parts are processed using special cutters held by hand.

Homemade lathe

DIY creation lathe allows you to make dishes, interior decor and furniture from wooden blanks. Such a device will be affordable alternative industrial projects, and will help you realize your creative potential. A homemade lathe can be made from individual components and parts:

- an electric motor used as an electric drive for the machine;

- a headstock, which can serve as an electric sharpener;

- tailstock made from a drill;

- stop for cutters;

- transverse guides;

- a frame made of metal profiles or beams.

Front and tailstock lathe are the main working elements, between which a wooden blank is placed. The rotating movement from the electric motor is transmitted to the workpiece through the front headstock, while the rear headstock remains static, responsible for holding the workpiece. If you equip a homemade lathe additional accessories– baluster, trident, copier and others, then its functionality will increase significantly.

The video below demonstrates how to make a lathe with your own hands.

If necessary, drill precise holes in metal, plastic or wooden parts, experienced craftsmen It is recommended to use a drilling machine. Unlike a drill, which vibrates strongly during operation, this device provides high-quality results, regardless of the material and thickness of the workpiece. You can make a simple drilling machine yourself using the same home drill, but installing it in a vertical position on a frame made of furniture board and attaching it to a metal stand. If necessary, such a machine can be equipped with an asynchronous motor.

As a rule, home craftsmen do not stop at making the machines themselves. Very often they work to improve existing equipment.

The video below demonstrates useful accessories for a lathe that expand its functionality.

Homemade metal tools for the home workshop

These do-it-yourself devices for the home workshop are designed to facilitate the metalworking process. They are usually made from scrap materials and tools.

Among the most popular devices are:

- pipe benders;

- press;

- vice;

- milling, metalworking, turning, drilling and thicknessing machines;

- devices for sharpening drills, knives and other tools.

With their help, a home craftsman can make practical devices for a summer house, garage, and also to equip comfortable home. Examples of useful machines and devices in the household can be seen in the photo below.

Homemade metal cutting machine

The video demonstrates how to make some useful household devices.

Taking into account the presented recommendations and drawings, any House master will be able to make useful devices for the garage and machines for his workshop, arrange an ergonomic space in it, and realize his creative abilities.

Order in the house depends not only on whether every thing is in its place. Every home needs periodic maintenance. If every mechanism in the house works like a clock, then we can say that the owner is fully fulfilling his duties. To maintain order, you cannot do without a workshop and tools. Some of them you can make yourself. The article will talk about the process of assembling tools that will allow you to equip your workshop.

What you can collect with your own hands

With proper skill, you can assemble almost any machine that is needed for processing wood or metal. They will differ from the factory ones in the assembly method, as well as in dimensions. Most often, large units are not required for home use. There is no problem in building your own milling machine, with which you can beautifully design various slats. Another necessary machine that can be assembled at home is a drilling machine. You can’t do without it if there is a need to drill precise holes in small workpieces. In some cases, assembling a machine involves making a holder for a hand tool, in others it can be assembled from scratch using motors from other devices.

Before you begin assembling any products for your home workshop, you need to clearly define what tasks are assigned to the workshop and what scope of work will be performed. On the one hand, this will allow you to decide what machines will be needed, and on the other hand, it will make it possible to find out whether the available space is enough or whether the workshop needs to be located in another room. It's good if it happens separate room, because noise from operating machines can irritate residents. The easiest way to build a workshop is in a private house, where you can use a basement or garage. U good master Everything is organized and in its place, so it is important to take care of practical shelving.

Storage items

Almost any surface in a home workshop can be used to store tools. Based on the location of organizers, the following types can be distinguished:

- wall shelves;

- racks;

- shields;

- floor organizers;

- ceiling shelves.

They can all be located in one workshop, which will make it possible to significantly expand the total area of the room.

Wall shelves

This home workshop design is the most common and frequently used. Building wall shelves is not difficult. The first step is to determine the wall where their placement will be most practical. For example, it could be a wall near which it would be impossible to place a shelving unit. You should not place a wall-mounted shelf in the workshop where you plan to build a shield for hanging hand tools. In some cases, a wall shelf can be placed right under the ceiling. Since shelves in a home workshop are designed to store heavy objects, and not soft toys, the structural strength should be higher than those used at home. For assembly you will need:

- corner 40×20 mm;

- board or chipboard;

- Bulgarian;

- welding machine;

- roulette;

- marking tool.

The first step is to draw up a sketch drawing indicating exact dimensions designs for the workshop, which are determined based on free space on the wall. The sketch also indicates the number of tiers that one shelf will have. The next step is to prepare the corner pieces for assembling the frame. A shelf for a home workshop in which the ends of the racks will be cut at 45 degrees will look neater. This can be achieved using a square or a special holder for an angle grinder. The first step is to assemble the side faces of the workshop shelf, which can be represented by rectangles or squares. It all depends on the chosen shape of the shelf.

The elements must be absolutely identical so that the design of the shelf for the home workshop is without distortion. After this, the sidewalls are connected to each other by four horizontal crossbars. In this case, the corner must be placed in such a way that the part with a length of 20 mm is at the bottom. It will serve as a support for the board. There is no need to rush to the workshop when welding the shelf frame. It’s worth starting with tacks so that the structure doesn’t move, and then weld it with a solid seam. An excellent assistant when assembling the frame will be corner clamps, which will keep the angle straight.

When the frame is ready, you need to determine how it will be attached to the wall in your home workshop. This can be done by drilling holes in the corner or welding special ears. The first option is more reliable. Next, the seams of the structure are cleaned in the workshop and the metal base is painted to prevent corrosion damage. The last step is to cut out wooden coasters, which are placed inside. The shelf is fixed in place in the workshop and is ready for use.

Shelving

Workshop shelving can be assembled in several ways. It all depends on the material used, and this could be:

- metal;

- wood.

Each of these materials is practical in its own way. At the right approach Wood can withstand significant pressure and weight, but the dimensions of such a rack in the workshop will be larger than that of a similar one made of metal. Assembling the entire structure in a home workshop begins with a drawing. In this case, it is necessary to correctly determine the depth of the rack. A comfortable depth is considered to be such that it is possible to reach the edge of the shelf in the workshop by simply extending your arm. Typically, this size does not exceed 50 cm. If the shelving in the workshop will have a ceiling height, then it would be appropriate to have a small stepladder that will allow you to safely remove the necessary tools from the upper shelves.

Note! On sale you can find ready-made shelving for the workshop that has a modular design.

This means that the number of shelves can be varied depending on needs. Often their purchase is cheaper if you take into account not only the cost of materials for self-assembly, but also the time that will be spent on this.

The number and height of shelves in a home workshop are determined by what will be stored on them. Each shelf can have its own purpose. For example, on the lower ones you can place devices or workpieces with a large weight. If it is a power tool, then it makes sense to make the height higher than the highest element that will be stored on the shelf. The assembly principle is similar to that used for wall shelves to the workshop. In this case, it is better to use a corner with larger dimensions for the racks so that the strength is greater. At the same time, it is important to correctly calculate the width of the shelving for a home workshop, so that when using corners with smaller dimensions for shelves, they do not sag.

Shields

Shields are one of the most convenient items you can use in your home workshop. The advantage over other storage methods is that each element has its own place and is in plain sight. The only disadvantage of such a system is the inefficient use of space. Compared to shelves, more of it is required, and fewer tools fit. This is why shields are best suited for storing the tools that are used most often. The advantage of shields for the workshop can be considered their certain versatility. On the shield you can place not only hooks for hanging, but also various small drawers for storage.

There are ready-made shields for sale for the workshop, based on which you can assemble your own version. For this you can use:

- sheet metal;

- plywood.

The assembly principle in each of these cases is similar, only the way of working with the material is different. If plywood was chosen as the base, then there are several ways to proceed. The first step is to mark the sheets that will be used in the home workshop. After that, they are laid out on the surface and the tool is laid out, which will hang on the shield. A fastening in the form of a self-tapping screw is screwed under each tool or it is outlined along the contour to make it easier to navigate later. Next, the sheet is fixed to the wall using self-tapping screws. For fastening, it is better to use bolts with hexagon heads and clamp the sheets through washers.

There is another version of the shield for the home workshop, which uses hooks instead of screws. This design can be considered more universal, since its configuration can be changed depending on needs. The best solution would be to purchase metal hooks in advance, which are used for shields in workshops. Depending on the distance at which the fixing tendrils are located on the hooks, the sheet is marked. Holes are drilled at the marked points. The shield is fixed on the wall in the home workshop at a short distance from the wall so that you can freely remove and put the hooks in their place.

The metal shield is assembled according to the model of the second wooden version. In this case, the work also comes down to drilling holes at the indicated points. In this case, it is better to use metal with a wall thickness of 0.8 mm. The weight of the tool can cause the metal to bend. There are several ways to solve the problem. One of them is to install additional spacers in the form of corners on back side rack. You can also assemble several separate smaller panels and install them side by side.

Ceiling shelves

Certain areas in home workshops are practically not used, or the ceiling height exceeds 2.5 meters, which will allow free placement of storage items on the ceiling. The easiest and most convenient way is to secure containers in which you can put small things. This is quite easy to do. To implement the entire project in the workshop you will need to make wooden boxes any size. The easiest way would be to purchase plastic containers that are perfect for these purposes. Except plastic containers, you will need metal I-beams. If these are not available, then a U-shaped profile can be used for the workshop. As a last resort, you can remove one wall from square pipe to achieve the required result.

Plastic containers for the home workshop have special edges along the edges, which can be used for fixing. Therefore, it is enough to simply attach the prepared profile to the ceiling in the workshop at such a distance that the containers fit between them. This design is not suitable for storing heavy objects, but a lot of material or tools that are rarely used can be placed there, freeing up space on shelves and racks.

Note! Floor organizers for the workshop can be presented regular boxes, in which there will be inserts divided into a certain number of cells. It is convenient to store fasteners in such inserts. But if there are enough shelves and racks in the workshop, floor organizers will not be needed.

Crafting table

This design is essential for any home workshop. It is on the workbench that all the magic of repairing and constructing any products happens. It is better to make a workbench for a workshop universal, since it will require processing not only wood, but also metal, but if the workshop area allows, then you can make two separate workbenches, which will be more convenient, since wood requires the most careful handling, and metal often requires force. Manufacturing process wooden workbench for the home workshop will be described in detail in several videos below. It is worth noting right away that to assemble such a structure for a home workshop, you will need some skill in working with power tools. A ready-made workshop workbench will support work with various systems fastenings

A simpler, but no less functional design for a home workshop can be assembled from metal. At the same time, it is easier to build additional holders for shelves and drawers on it. Above is a drawing that can be taken as a basis. Dimensions are adjusted depending on how much space is available in the workshop. The height of a workbench for a home workshop is selected individually, but most often 80 cm is enough, which allows you to work with objects at waist level. It is better if the workbench is securely fixed to the floor. It is also worth setting it according to level. If on metal workbench If wood processing is planned in the workshop, then special carpentry vices are additionally installed where it will be convenient. Can be used portable version a vice, which is fixed with clamps.

Advice! Great option there will be production wooden table top to the home workshop, but metal can damage it.

To protect the wooden surface of the workbench, you can lay a metal sheet on top through a gasket made of OSB boards. The thickness of the metal that will be used as an overlay should not be less than 1 mm.

Workshop machines

Below we will describe the general principle of assembling machines for a workshop, which can be taken as a basis, and assembly can be done from available materials.

Wood and metal lathe

It is worth saying right away that on such a lathe in a home workshop it will be possible to process only small metal workpieces. An important part of the machine for the workshop, which will ensure stability of processing, is the bed. You can make it yourself or use a factory one. For self-made you can use a profiled pipe or a strong corner. Two elements are placed on suitable distance and are securely fastened to each other by transverse elements. Examples of machine designs for a home workshop are visible in the photos above and below.

As a motor that will rotate the part, you can use a unit from an old washing machine, pump or some kind of machine. A powerful drill chuck can be used as a tailstock. In this case, it will be possible to insert a cone or drill into it, if required during processing. The headstock can be purchased factory-made or made according to the model in the photo.

In this case, a metal axle will be required, it is better if it is made of hardened steel. You need two holders with bearings for the axle. On one side, a pulley is fixed, and on the other, a chuck into which the workpiece will be clamped. The engine on such a workshop machine is installed next to the headstock, and the force is transmitted through a belt. The speed can be varied by using a frequency module or by moving the belt over a pulley. You will also need a support element, which is made according to the schematic drawing below.

Video about self-assembly wood lathe is below.

Milling machine

A milling machine for a home workshop is also quite easy to assemble. One option is to use ready-made hand router, which is indispensable for the owner who likes to make something out of wood in his workshop.

For manual machine You can make a special workbench for your home workshop. The photo shows an example of such a table. At its core, it is a small table in which there is a hole for a cutter and a mount for the router itself. If you wish, you can do this in the workshop and on a ready-made workbench. It is important to choose the most comfortable spot for fixing the router. During fastening, it is necessary to correctly calculate the maximum overhang of the cutter. When working this way, you will need to lift the factory support completely on a hand router. Switching on and off can be done via an extension cord with a switch. The disadvantage of this method is the need to manually adjust the speed directly on the router itself. A video about a homemade milling machine is below.

Advice! If you have an engine of the required power and a frequency converter, you can build a stationary milling machine in the workshop.

To do this, the motor is attached to the bottom of the table. A cutter chuck is mounted on the motor shaft. The connection is made through a frequency converter, which will vary the speed.

Drilling machine

A drill can be used as a drilling machine in the workshop. But for this it needs to be properly fixed. This can be done using a holder, which can be stationary for the workshop or portable. There are many various options assembly of such a drill holder for the workshop. One of them is shown in the video below. Assembly will require materials that are within walking distance in every hardware store.

A circular saw

A stationary circular saw for a workshop can be made in a similar way as a holder for a hand router. It is enough to make a slot in the countertop for the slab sheet and mount it when required. The only drawback of this solution is the reduction in cutting depth. This can be corrected by installing it on a metal tabletop that is smaller in thickness. A video of the assembly of this design is below.