How to make furniture from logs. Log table: technology and DIY manufacturing scheme. Fantasies on the topic: how to make a table from logs with the least amount of time, effort and money

Since this is furniture made from waste, for obvious reasons, the most painstaking work is considered to be the process of selecting the material, which will need to be combined not only in size, but also in color, as well as surface texture. Also, in the process of assembling log furniture with your own hands, quite a lot of time is spent on performing operations to connect parts ( structural elements). More details about production process Find out further using the example of making a backrest makeshift bed from logs.

§ How is wood selected? Important point!

Trees exist wherever a person lives, unless, of course, it is a desert or steppe. There will always be some tree care companies, energy companies, farms, construction sites, where areas are cleared for plantings, and, of course, landfills. Also, do not forget about the forest washed ashore. To ensure that log furniture is of high quality and durable, you should carefully choose the wood. You should not take timber with traces of damage from woodworms; all bark should be peeled off on site as it may harbor various insects, whose appearance in the workshop is undesirable.

After selecting the base material, manufacturing of structural parts, for example, backrest log bed, takes only a couple of hours. First you need to cut out the posts, horizontal frames, and the balusters of the bed headboards. After this, use a metal brush to remove all dirt and roughness from the surface of the workpieces. Then the balusters and trims are equipped with tenons cut using special equipment. The electric planer must be attached to a loop so that it hangs over the part itself. The part is clamped on the frame lathe. The length of the tenons of the straps should be 5 cm, and the tenons of the balusters should be 4 cm.

After this, using a two-handed electric drill with a Forstner drill, you need to drill sockets for the tenons in the legs and straps. The peculiarity of this operation is that, unlike bars and boards, which have certain standard sizes, all logs are different and the nests in them must be selected one at a time, carefully adjusting them to the mating parts each time.

Final assembly of the product. Dry assembly, gluing log furniture, as well as the installation of clamps, are similar to normal carpentry operations. There is one caveat here though. After coating the nests with catalyzed gap-filling glue (casein glue with transverse intermolecular bonds is mainly used) and assembling the structure, take the backrest by the horizontal straps and hit the backrest firmly with the leg on the floor. Only after this operation can we consider that the spikes are firmly seated and grasp the clamps.

Particular attention should be paid finishing log furniture. Wood is sanded with 80 micrometer abrasive, cedar is sometimes sanded with 120 micrometer abrasive, and maple butcher blocks, as well as sawn beams from recycled materials, are sanded with 220 micrometer sand. The wood is not stained and therefore retains its natural warmth and reliability. For even greater durability of furniture from waste, the logs are covered with several (mostly two) layers of polyurethane. On chairs and tables made from sawn beams, as well as maple butcher blocks, a couple of layers of teak oil are applied with intermediate sanding of each layer, briuox wax (paraffin) and then rubbed with a leather wheel to a perfect shine.

There are enough companies and individual craftsmen on the market who manufacture such furniture. It is environmentally friendly, practical and very beautiful, looks great in any interior. It can be purchased at finished sample or order according to your own preference. Approximate prices: chairs and armchairs made of logs - from $100, cabinets and chests of drawers - from $110, log beds - from $280, tables with benches - from $220. The cost depends on the type of wood used, its quality, the amount of materials consumed, the amount of work and the complexity of the design. Therefore, the price may vary greatly among different manufacturers.

In addition to furniture, you can also make your own house from waste. Trend on maximum use wood waste is especially relevant in our time. After all, this concerns natural materials And natural resources, which take a long time to reproduce.

Tree natural material, which fits naturally into . Garden furniture made of logs - inexpensive option for landscaping the site.

It is necessary to try to preserve the original shape of trees and knots, to emphasize the elegance of the structure of the material

It is necessary to try to preserve the original shape of trees and knots, to emphasize the elegance of the structure of the material To make, you need skills in working with power tools, desire and imagination. The material can be found everywhere, it can be an old tree on the site, or in a forest area near the house.

A good addition to a massive log will be unusual shape driftwood, you can look for them on the shores of reservoirs. They will enliven the furniture composition and add a touch of originality.

The advantages of wooden furniture include:

- It can be made from available materials, low cost.

- The aesthetic appeal of wood, the originality of garden sets.

- Durability of log furniture, provided the wood is properly processed.

- Fits naturally into the natural landscape.

Depending on the source material and its size, the results are different variants garden furniture.

DIY garden furniture made from logs

Wood is a unique natural material. After special processing it manifests itself beautiful texture.

Sets of log tables and benches: 15 photos

They use not only logs and driftwood, but also saw cuts. Tabletops and bench seats are made from dies. They are filled with transparent epoxy resin. Such items are exclusive and durable.

There are three rules for processing logs:

- The bark, especially from old trees, is removed using a metal scraper or spatula. Under the layer of bark there are nests of insects and pests. Once the bark is scraped off, the beautiful texture of the material is revealed.

- from penetration of moisture and pests. Impregnations, stains, and varnishes serve as additional protection and help the texture of the material to appear and emphasize the natural pattern.

- Furniture surfaces that come into contact with the body must be sanded to avoid splinters.

Read also

Arrangement of the yard of a private house

You need to be creative when making furniture. Nature itself is a good master.

Log furniture options:

- deliberately rough sets;

- combined: log with snags or saw cuts;

- furniture made from processed, sawn tree trunks.

A separate set is unique, since each tree in nature is unique, different in texture, shape, size.

Making a bench

They are installed in the most picturesque corners garden The simplest option for a bench for a summer cottage is to cut a solid trunk in half with a saw and install it on a base of stumps.

Bench options: 9 photos

Assembly instructions

For a strong connection between the seat and the supports, tongue-and-groove joints are cut into them. Additionally, you can mount a backrest from the second part of the log, securing it to thinner logs.

Looks interesting combined option. The seat is made from a cut trunk, and the back is made from treated driftwood. Installed on stumps with remains of horse taps. The bark is first removed from the wood and sanded. Treat with anti-moisture agents and allow to dry. Then they are opened with stain and moisture-resistant varnish.

The result is an expressive product that will decorate any landscape. Such objects look almost like a natural element.

Ready-made drawings of benches

If you decide to make your gazebo more comfortable and sophisticated at the same time, a log table will be an excellent embodiment of your idea. Another place where such garden furniture it will look like a bathhouse. Below we will talk about how to make a table from logs with your own hands.

To better understand what exactly the table material looks like, you need to remember the real Russian wooden house. The same logs as at home are used to make tables and benches for the garden. A table made of such material will be very practical and will also decorate any log house or summer cottage. The use of such furniture in a bathhouse will provide it with even greater convenience, comfort and improve its design.

A log table can be placed both outside, directly in the garden, and inside the house, making the interior more original and sophisticated.

If you decide to install such furniture inside a building, it is best to assemble it there, since due to its considerable weight, it will be quite difficult to bring it in from the street. DIY log table photo and drawing.

Before you start making a table from logs with your own hands, you need to develop a sketch of it. You need to think about what size table you would like and how you see it. It is best to make a three-dimensional drawing, it will especially help you if you have decided to grind logs for your furniture. If you are not able to make a three-dimensional drawing, it is quite possible to get by with a simple one, but you should remember that in this case you will need to draw a view of the table from the front, top and side.

Before you begin assembling the table, you need to properly prepare the material, namely the logs. In order to get rid of small irregularities and sawdust, you should plan the logs using a plane, after which you need to process them sandpaper. In order to sand it, you should first use coarse-grained sandpaper, and only then use fine-grained sandpaper.

The logs must be prepared according to the dimensions indicated on your drawing.

Since longitudinal grooves in logs are made using special tools, which are not accessible to everyone at home, it is better to create flat surface minimum 4 cm wide.

Logs need to be cut at a certain angle, namely 45 degrees, and they will be shorter in size in relation to the log located in the center. Next, use a file to remove the corners. If you leave them, you cannot avoid hitting your knees on them while using furniture.

To ensure the stability of the log, it is necessary to drill holes through it in order to pass the reinforcement through them. The log located at the very bottom does not need to be drilled all the way through; you should make a hole only up to its middle. In order to connect the logs, you can use any reinforcing bars, including those that you still have after some construction work.

The holes should be made strictly at an angle of 90 degrees with an interval of 30 cm, and when placing logs on top of each other, all drilled holes must coincide.

After you've finished everything preparatory work and pre-processing of the material, you should proceed to the next step, namely assembling the table.

You should check all prepared parts according to the drawing, and then assemble the elements according to your sketch.

To begin with, you should put in Right place the first and lowest log into which you need to insert reinforcement and place the logs on top of each other. All assembly work must be carried out strictly according to the drawing, so that there are no deviations that could subsequently affect the quality assembled table.

Once all the logs are in place, the rebar should be sticking out of the log. It is necessary to make a mark on it closer to the hole of the last log. Next, the reinforcement must be removed and cut at a distance of 5 mm below the marked location. After this, the entire workpiece must be disassembled.

As a result of such actions, the reinforcement that is located inside the logs will be glued to them, which will provide additional rigidity and stability of the structure. The top hole should be completely filled with glue so that there is no free space.

Fastening the table cover

A quick solution for a table top is a sheet of chipboard that needs to be cut required sizes and place it on glue, fasten it with screws, or nail it. But this method is only suitable if you do not plan to place heavy objects on the table that could damage the sheet, and also if its dimensions are no more than a meter in length and width. When large sizes The chipboard sheet will need to be further strengthened to prevent it from sagging. The support can be made from beams, and they do not require processing. Thanks to this strengthening, not only the lid, but also the logs will have greater rigidity. You determine the number of bars yourself, depending on the size of your table. You can secure the beams to the table frame using self-tapping screws or nails.

However, such a table cover will not provide you with the integrity of the design, since it will stand out against the general background of the logs. Consequently, the upper part of the beams will give a completely different, more aesthetic appearance to the entire product.

The bars must be the same in length, and their thickness must be at least 2 cm. Such material for the top of the table will serve not only as a cover that can withstand any weight, but also as an additional support for the entire structure.

The beams should be attached to the logs in such a way that they do not form cracks, but form a single sheet. Next, you can proceed to processing the table surface.

First you need to clean it with a plane, and then you need to use sandpaper to get a smooth finish on the table top.

Having secured all the beams, it is necessary to clean their edges with a file in order to remove all sharp corners and give the product best view and provide more practicality.

If you have a tool such as a drill, and you have a special attachment for grinding, then you should definitely use it. But in case of its absence, you will have to achieve a smooth table using sandpaper.

After you achieve the desired result, all you have to do is coat your product with varnish. First you need to clean the table from debris and dust, and then degrease it. You can use absolutely any varnish intended for a material such as wood. You can use a brush for application or a roller, but it will be most convenient to use a spray can, which will ensure even coverage of the product. After you have covered the table with several layers of varnish, you need to let it dry.

Each owner of a private house of urban or country type, country or personal plot sooner or later faces the need to improve its territory. And we are not talking about creating beds and flower beds, planting trees and shrubs, but arranging comfortable, but at the same time practical areas for relaxation, preparation and consumption of food on fresh air. It’s difficult to imagine a landscaped area without garden furniture, but not everyone can afford to buy one, and it’s much more pleasant to sit on a bench you made yourself or dine in the fresh air at a table that didn’t cost you a penny to make. In this publication, we have collected many options for garden furniture that you can make with your own hands. Possessing only available materials, a small set of tools and a great desire to make your site landscaped, comfortable and aesthetically pleasing.

In order for garden furniture to appear on your site, capable of becoming not only a reliable piece of exterior furniture, but also a reason for the pride of the owners and the envy of neighbors and guests, not much is needed - waste material, perseverance, a little imagination, work and effort. In this article you will find examples of making garden furniture from wood, construction pallets, used household items.

Choosing material for making country furniture

In order for hand-made furniture to fit organically into the existing image of a summer cottage or private yard, it is necessary to take a responsible approach not only to the manufacturing process itself, but also to the choice of material. The most versatile and at the same time very malleable material from the point of view of processing is natural wood. The advantage of wood is that it can fit perfectly into any stylistic direction in landscape design. And this can be achieved through a variety of design options - from massive furniture, made from logs to light and elegant products woven from wicker or twigs.

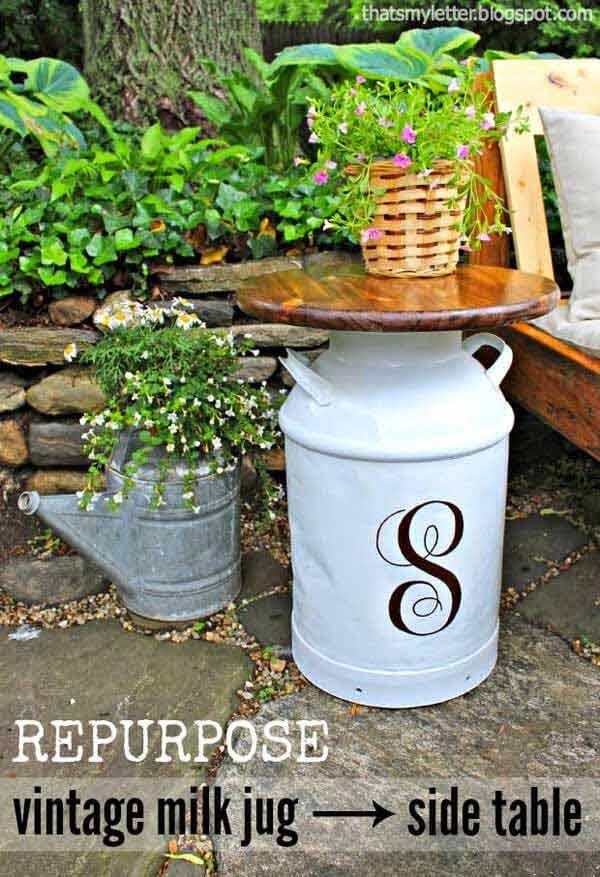

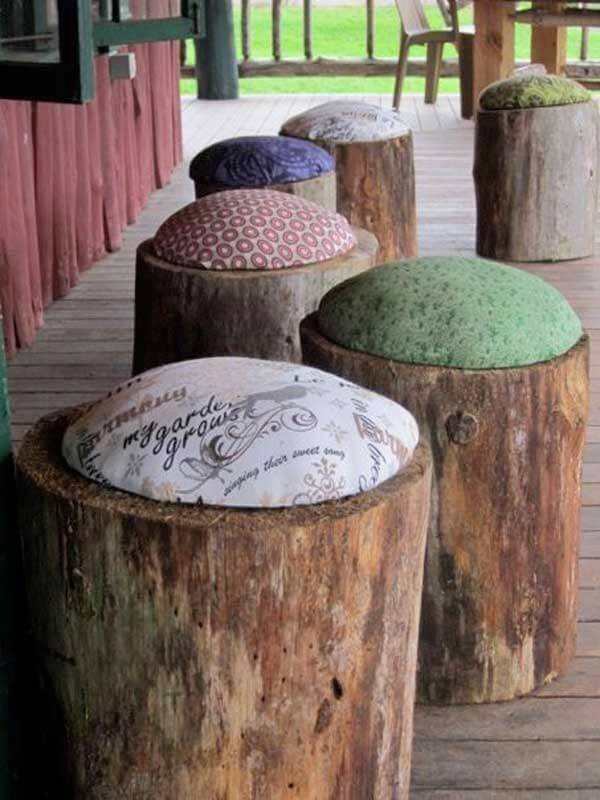

The advantage of wood for creating furniture with your own hands is that it has many manifestations. You can create a piece of furniture with minimal processing of the material in the shortest possible time. For example, ordinary hemp can be turned into stools or small stand tables. You just need to make sure that the surface of the new pieces of garden furniture is perfectly hewn and becomes safe for use.

You can create garden furniture from branches and twigs...

Or logs and large timber...

Benches and benches are an integral attribute of country life

Even a very small backyard needs outdoor furniture to sit on to enjoy the fresh air, watch the sunset or watch the sunrise. Well, at the site big family or in the courtyard of hospitable hosts, where companies gather, it is absolutely necessary to take into account the possibility of seating several people.

One of the most simple ways creating benches and benches - use wooden beam and cinder block with square holes. A bench or bench can be assembled like a construction set; you don’t even need to use any tools or fastening mortar or construction adhesive. The advantage of such structures is not only ease of installation, but also portability - you can easily disassemble your piece of garden furniture and move it to another place or put its parts in the shed until the new warm season.

If you put soft seats on a bench made of cinder block and timber and sofa cushions, then an ordinary hard garden bench turns into a convenient, comfortable sofa.

By combining materials for garden furniture, you can increase strength and improve appearance products. For example, together with wood in one modification or another, you can use metal constructions, for example, parts of beds (backs, legs).

Outdoor dining area

Any dish tastes better in the fresh air. Every owner of even a tiny backyard tries to create an environment in which they can have meals outdoors. outdoors, even if we are talking about short breakfasts. Depending on the needs and size of your family, you can arrange either a small area for short meals or a spacious dinner table for receiving guests in the fresh air. It is noteworthy that both options can be implemented on your own.

One of the simplest, yet practical ways to organize lunch group in the fresh air - making a table, together with benches. The model shown in the photo will require minimal amount material, but at the same time it will be quite spacious. The only drawback of such a dining group is that if you need to increase the number of people sitting at the table, you can only do this with 2 seats (you will need chairs or stools).

Equip dining area or a segment for short meals (breakfasts and afternoon snacks) can be like a bar counter. This is easy to do using building blocks and wooden beams or boards. The only thing that needs to be selected for such a tabletop is bar stools with the appropriate height.

Relaxation area in a summer cottage or garden plot

Everyone associates outdoor recreation with different things. For some it’s gatherings with friends and neighbors, for others it’s reading on a slightly swaying swing, for others it’s just sun loungers. air baths necessary. For all options for active and not so active recreation, you can make furniture with your own hands, and even from improvised means at minimal cost.

One of the most common ways to create garden furniture for a recreation area is to use construction pallets or pallets. The advantage of such an assembly is its simplicity - wooden blocks have already been formed in terms of future armchairs and sofas. Well, build coffee table even the owner of a dacha or any other land plot who had never held a hammer in his hands before. You can even use construction glue to hold the elements together.

Another advantage of using construction flights for the manufacture of garden furniture is that you can get the material at a very low price or completely free, because we are talking about used products. You just need to take care of thoroughly cleaning the surfaces, leveling and lightly polishing, and impregnating the material with antiseptics against rotting.

From construction pallets you can create entire compositions for outdoor recreation areas. This can be a spacious corner complex, designed like a sofa, comfortable chairs And coffee table. It is enough to put soft pillows and seats in armchairs and sofas to create a living room environment right in your country house or garden plot...

With help wooden pallets you can arrange an area not only for relaxation, but also for sleep. A summer bed or just a layer of construction pallets with a mattress is an excellent opportunity to create a bedroom in the fresh air - just take care of a canopy over the sleeping area to protect from the sun.

It’s easy to build a comfortable swing from old pallets. You can tie them on ropes or chains to the roof of a canopy or gazebo, on a terrace, or simply under a tall, spreading tree with thick branches.

Slightly less popular, but still practical way arrangement of a summer cottage with garden furniture - the use of construction wooden reels. Chairs can be made from them...

A log table is an excellent design and practical solution for your summer cottage if you want to place it in a gazebo.

This kind of DIY garden furniture made from logs also looks great in a bathhouse.

How to make a table from logs with your own hands will be discussed in our article.

What is a log table and how can it be used?

You've probably seen wooden frame– a house in a classic Russian style.

From the same logs you can make a beautiful and comfortable table along with benches, at which your family or friends invited to visit can sit.

A table made of logs will look great in dacha gazebo, and in the courtyard of a log house.

Using a log table is very important and convenient in a bathhouse.

There, the table will fit well not only in design - it will fit perfectly in its functionality.

The table can be placed both on the site and directly inside the house.

It is quite easy to install, so if you plan to install the table inside the house, we recommend assembling it there, since finished design It weighs quite a lot, so it will be at least physically difficult to carry it.

Drawing

Before you start working with a log, you need to make a drawing.

Think about what the table should look like. Write down your desired dimensions.

It will be nice if you can make a three-dimensional drawing.

This is necessary if you plan to grind logs.

A regular three-dimensional drawing of a table can be replaced, but then you will need to make three drawings: the length, height and width of the table.

How to prepare logs?

To make the table look beautiful, the logs need to be planed with a plane; You can then go over the wood with sandpaper to get rid of small sawdust and burrs.

If you want to polish future table, then start with coarse sandpaper, then go through fine sandpaper.

All logs must be cut according to the dimensions of your drawing.

Since longitudinal grooves in logs are made using special tools, we do not offer you this idea.

Since longitudinal grooves in logs are made using special tools, we do not offer you this idea.

More affordable way- this is using a plane to create a flat surface at the joints of logs.

The surface should not be narrower than 4 cm.

To make the table comfortable, the logs must be cut at an angle of 45 degrees, making them shorter to the log that will be in the center.

Then get rid of the corners. A file will help you with this.

If you leave the corners, then when using the table you will hit your knees against them.

In order for the logs to hold well, they need to be drilled through holes, through which the reinforcement will be passed.

There is no need to drill through the lowest log. It is enough to make a hole to the middle.

The thickness of the reinforcement may vary. The one left over from the construction of the house will do.

Please note that when placing logs on top of each other, the hole should match, but it must be drilled at an angle of 90 degrees.

The holes are made at a distance of 30 cm from each other.

How to assemble a table?

When the holes are drilled and all preparatory work is completed, you can begin directly assembling the table from logs.

Let's start assembly. Look at the drawing.

Now the lower log is placed, the reinforcement is inserted into it, the logs are placed on top of each other.

Now the lower log is placed, the reinforcement is inserted into it, the logs are placed on top of each other.

For reliability, you can use glue. You stack the logs according to the drawing.

Is the reinforcement quite long and sticks out? Don't be alarmed, because that's how it was intended.

You need to saw the reinforcing rod near the hole closer to the log.

Then the rods need to be pulled out and cut 5 mm lower than the mark obtained as a result of the cut. Now the structure is disassembled.

Glue is poured into the bottom of the holes in the lower log.

All holes are also glued, after which you need to reassemble the structure and place the remaining logs on the reinforcing rod.

The result is that the reinforcement is securely glued to the logs, and does not dangle inside the holes.

Fill the top hole with glue until it is full.

How to secure the top of the table?

If you are looking quick way, and you won’t put anything heavy on the table, then you can take a sheet of chipboard, adjust it to the size of your table and glue it to the logs.

You can secure the sheet with nails or screws.

However, this method of creating a surface is only suitable if the dimensions of the table are meter by meter.

If the table is larger, then the chipboard sheet will require additional support so that it does not sag.

It can be made from beams. You don't have to process them.

Find even ones and nail them to the sides of the table.

The beams will not only support the chipboard sheet, but will also make the entire structure more rigid and prevent the logs from moving.

The beams will not only support the chipboard sheet, but will also make the entire structure more rigid and prevent the logs from moving.

You can guess how many bars you will need. Their number increases depending on the size of the table.

The larger the table, the more beams you need for it. They can be secured with nails or self-tapping screws.

A sheet of chipboard is, of course, quick, but, you see, it’s not very aesthetically pleasing: nevertheless, a table made of beams will look better if it looks like some kind of monolith.

And then you can bet anything on it. If you want just such a table, then the second option for creating the upper half of the table is suitable for you.

The upper part can be made of beams. All that is required is to select beams of the same height, the thickness of which should not be less than 2 cm.

The upper part can be made of beams. All that is required is to select beams of the same height, the thickness of which should not be less than 2 cm.

Such bars will simultaneously perform two functions: they can serve as a reliable support for the table and at the same time be top part that can withstand any load.

The beams are nailed to the logs so that there are no gaps between them.

Afterwards you can start working with the surface.

Clean it with a plane, then start sanding with sandpaper. Need to get smooth surface, because this is your future table.

After the beams are secured, run a file along their edges. Sharp corners can cause splinters and are uncomfortable to use.

The table is almost ready.

If you have a drill with a special sanding attachment, you can use it, if not, sand with sandpaper until you get a smooth surface without rough edges or splinters.

If you have a drill with a special sanding attachment, you can use it, if not, sand with sandpaper until you get a smooth surface without rough edges or splinters.

Well, then all that remains is to varnish the table.

To do this, wipe the surface of debris and degrease it.

Any varnish intended for wood products will do.

It can be applied with a brush or roller, but it is most convenient to spray from a spray can.

One or two layers is enough. Let the varnish dry.

Your DIY log table is ready!

Video about wooden garden furniture