Garage interior decoration. Finishing the inside of the garage - a review of successful solutions for your “car home” Cover the inside of the garage with plywood

A garage should not only be comfortable and safe place for car storage. Many car enthusiasts spend a significant part of their free time in it, so doing the interior decoration of the garage with your own hands should create cozy atmosphere for work and visually brighten and expand the room.

A wide range of facing building materials will give you the opportunity to harmoniously arrange the interior space according to your taste and capabilities.

Concrete floor in garage

A concrete base is the first step to decorating your garage. This coating is inexpensive and durable; it withstands harsh operating conditions. But it also has significant disadvantages: increased dust formation and poor resistance to dirt.

The top layer of concrete gradually wears away, and the floor becomes covered with an unsightly grayish coating. Dirt and chemicals, which abound in the garage, are absorbed by the coating, which contributes to a stable and unpleasant smell in room. But this state of affairs can be avoided if you protect the concrete base with special means.

Reinforced concrete floor in garage

This can be impregnation or paint. But it is worth saying that their service life is short - from one to three years. Therefore, you will have to constantly repair the floor. If you are not happy with this prospect, you can cover the concrete with self-leveling polymer floors. They have excellent performance characteristics and have a service life of tens of years.

The main thing when pouring a concrete base is to strictly follow the technology. Otherwise, the coating will begin to crack and collapse in the future.

The best base for a garage floor is solid iron. concrete slab, resting on the base of the building. However, pouring it will require significant effort, special equipment and the invitation of a team of workers, all of which will increase construction time and its cost.

Optimal solution:

The floor is arranged at the level of the base edge or slightly higher. The thickness of the concrete should be about 8-10 cm. Before pouring the solution, the soil is thoroughly cleaned and leveled horizontally. If backfilling is necessary, it is done with sand or small crushed stone, followed by compaction.

The M200/300 grade mixture can be ordered ready-made at a concrete plant or prepared independently. Based on the following proportions: 1 share of cement, 2 shares of sand and 3 shares of fine gravel or crushed stone.

To make the coating even, tighten the laces or level them with strong shaped pipes. Don't forget to lay out the reinforcing mesh. Fill the concrete with cards, trying to do it continuously. If you have installed beacons, lay the solution in strips between them.

After the mixture has set, thoroughly rub and smooth the coating. It will be possible to install the finishing coating on the base 28 days after it is poured.

Important! Outside the garage, along its perimeter, be sure to make a blind area, the width of which should be at least 60 cm. Technologically, it is made in the same way as the floor. On the blind area, 4-5 cm of concrete is sufficient; its plane should have a slight slope of 1.5-2°, directed away from the walls of the garage. This is necessary to drain melt and rainwater from the building.

Garage interior lining

Technologically, finishing a garage with your own hands serves, first of all, not to decorate it, but to protect it.

The operating mode of this structure is extremely harsh and the floor is often exposed to the strongest chemical substances– fuel, technical oil, antifreeze, moisture and temperature changes. And the probability mechanical damage very big. Therefore, the cladding of the internal surfaces of the garage must provide effective protection against all destructive factors.

First of all, we must take into account that this room should be equipped according to the strictest safety standards for the car and, of course, its owner.

The interior cladding of the garage should be made only from building materials that:

- are not flammable;

- are resistant to chemical influences;

- resistant to dirt and does not absorb odors;

- easy to wash and clean;

- are resistant to shock and mechanical loads.

The list is substantial and significantly limits the choice of materials suitable for cladding garage surfaces. The economic factor also plays an important role in the final choice.

- One more nuance. You shouldn’t put too much trust in glossy publications, which often show examples of garage decoration that are more reminiscent of the living room of an expensive country cottage. Snow-white floors and ceilings look impressive, but in reality you will quickly lose all this beauty.

- White color is extremely demanding when it comes to cleanliness in the room. therefore, what looks so great in a photo in a magazine will lose all its luster after a very short time.

- You should remember that color is a fundamental factor in creating harmonious interior in any type of premises. With its help, you can play with space and expand it visually. Moreover, facing in warm and light colors will help hide many coating imperfections.

- Another the most important condition the right choice is an indicator of the strength and durability of the cladding. This rule especially applies to small garages, where everyone square meter operated with maximum load.

- It is recommended in such rooms to make maximum use of various wall-mounted and floor structures - shelves, mezzanines, cabinets. In turn, similar internal structure garage presents special requirements to finishing its surfaces.

How to veneer a garage with traditional plaster

Plastered and painted garage walls

Covering the walls of a garage with brick walls, is performed in the traditional and simplest way. To level out unevenness and protect the walls of a structure, a variety of plaster solutions which form a durable and reliable coating on them.

Additionally apply on top of the mixture protective layer paints. This is the most inexpensive and easily accessible way to cover any walls with your own hands. It is also suitable for surfaces made of reinforced concrete, gas blocks and foam blocks.

Installation

Sheets of material are fixed using wooden or metal sheathing, screwed with self-tapping screws to the surface of the walls of the room. It is worth noting that this is the most effective way of cladding metal garages, as it allows you to easily insulate them by placing slab insulating material between the frame and the lining.

Among the disadvantages of the coating, it is necessary to highlight weak impact strength and significant narrowing internal space at least 8 cm. It is also necessary to carefully monitor the location of the frame beams in order to easily install hanging systems - shelves, mezzanines, cabinets.

When you do the interior decoration of a garage with your own hands, it is better to use special ones designed specifically for it to line the ceiling. plastic panels. They are cheaper, although they are less durable. But this is not so important, since the ceiling does not experience mechanical stress.

Summing up

We hope our article was useful to you. In order to more accurately understand the technological and practical issue, our website provides detailed photo and video instructions in which you will find useful information on this issue.

Photo gallery

86544086

Besides the main one purpose of construction- comfortable and safe storage of the car; - the garage also performs other functions.

When troubleshooting and breaking down a machine, the room turns into workshop with all its attributes: heavy tools, bulky mechanisms, dismantled and spare units, stained with motor oil.

The constant presence of flammable fuel in the car tank and in spare cans places increased fire safety requirements on materials finishing interior walls , their resistance to toxic chemicals.

How to decorate the walls in a garage inexpensively? Nowadays, the choice of finishing materials is so great that we will focus only on some of the most budget materials for covering internal walls.

At the same time, we remember the key requirements for garage finishing: firmly, inexpensive, Beautiful.

Wooden lining

Wooden lining, the ultimate dream of a garage owner just 15-20 years ago, has long been lost among modern plastic descendants.

How to decorate the walls in a garage cheaply? Can tree. After all, this material is high-quality, durable and aesthetic. Polished panels made of precious wood decorate the interiors of palaces and the interiors of expensive limousines. Traditionally, saunas and bathhouses are lined with wood with low thermal conductivity to avoid getting burned on the walls.

But in a garage, where there is already an abundance of flammable substances, using wooden lining, and even impregnated with drying oil and varnish - extremely unwise. In such a room it will be dangerous not only to carry out any welding work if necessary, to install a heating stove, but even to simply smoke.

Timeless technology

However, modern types plastic linings, composite polymers and metal, traditionally continue to be copied wooden boards and panels, although the design imitates both brick and stone.

It's so universal, time-tested the form allows you to use best quality, inherent clapboard- it is easy to mount on a wooden beam sheathing.

It's so universal, time-tested the form allows you to use best quality, inherent clapboard- it is easy to mount on a wooden beam sheathing.

Another advantage of timeless technology is that the lathing allows comfortable install any insulation under the lining, hide cables and pipes engineering communications, ventilation ducts.

All types of lining, despite the differences in materials and profiles, are similar in installation principles: ridges and grooves at the ends of the panels allow them to cover walls no gaps. Each subsequent panel also hides the fastening elements of the previous one.

Metal lining

Such siding has all the advantages metal products- increased strength, durability, resistance to aggressive environments and temperature influences, non-flammability.

The disadvantages of metal are also presented here, the main one being susceptibility to corrosion. Metal lining is made of aluminum and steel.

Corrugated sheet

How to line the inside of a garage cheaply? One of the options - durable corrugated sheet. These are steel profiled sheets with protective polymer coating. Like lining, corrugated sheeting can be fixed to a wooden sheathing. And the speed of installation will be ensured big sizes sheets.

Vinyl siding

Filling composition PVC panels(short for the term PolyVinyl Chloride) - non-flammable materials. The panel melts, but only smokes without formation open flame. In the event of a fire, such smoke can extinguish the fire that caused it, displacing oxygen from the air in the room. But this toxic smoke is also harmful to human health. dangerous.

However, garage owners are willing to buy PVC panels for finishing walls, both internal and external, not for experiments with fire.

Wonderful vinyl siding meets our requirements “Durable, inexpensive, beautiful.”

Wonderful vinyl siding meets our requirements “Durable, inexpensive, beautiful.”

Moreover, it is waterproof, does not rot, does not warp due to temperature changes, is resistant to contact with garage chemicals, does not require painting or maintenance, and can be washed from almost any contaminant.

This siding will last for decades.

PVC panels They also exclude nostalgia for the good old lining. The volumetric imitation of the texture and shades of wood on the surface of the panels is indistinguishably realistic. Except they don’t smell like pine...

IMPORTANT: Price plastic siding depends on the color. The brighter and richer color palette panels, the more expensive they are. This is explained by the high cost of high-quality polymer dyes.

Conclusion

Installation of almost all existing various types of panels for finishing garage walls is carried out using a single simple technology for attaching panels to the sheathing. Choice of siding type and material decorative panels it is not the completely simple installation that affects, but only your preferences And financial opportunities.

Having prepared everything necessary materials, tools and fasteners, finish with your own hands garage walls one day you can too. Having tightened the last nut on the unit, which you have been fiddling with since the morning, you sit comfortably in a well-worn chair and wearily unwrap the bags with lunch you took to the garage. Any minute now a neighbor friend will come up and the conversation will flow.

During such leisure hours, the garage performs its most enjoyable function as a motorists' club.

Your friends will be surprised and happy for you when they see a new girl wall cladding! And you, as an authoritative expert, will tell them about the features of the choice inexpensive materials finishing, their properties and other qualities - because now you know all this.

Garage for the car enthusiast – important room which requires proper finishing. In addition to vehicles, other important items can be stored here: spare parts for cars, tools, household items that are a pity to throw away. All this requires reliable storage. The article will tell you what non-standard ways to decorate a garage from the inside.

Finishing the inside of the garage is necessary to preserve heat in the room and protect it from dampness. Without finishing work, the humidity in the room will always be elevated. Due to dampness:

- The process of rotting the car begins.

- Rust appears on spare parts for it.

- Tools deteriorate.

- Other things become unusable.

Finishing works not only create an aesthetic appearance in the garage, they improve the hygienic conditions in it. Working in a warm, well-maintained garage will be more convenient, comfortable and safer.

Requirements for finishing materials

You cannot purchase the first material you come across for finishing the inside of the garage. This is due to the increased safety rules in it. It contains combustible, flammable materials, and any spark can lead to unforeseen consequences. Material requirements for interior decoration garages are presented in the table:

Alternative materials for wall decoration

Standard garage wall finish:

- Plaster.

- Tile.

- Lining.

But besides this, you can use other options, such as:

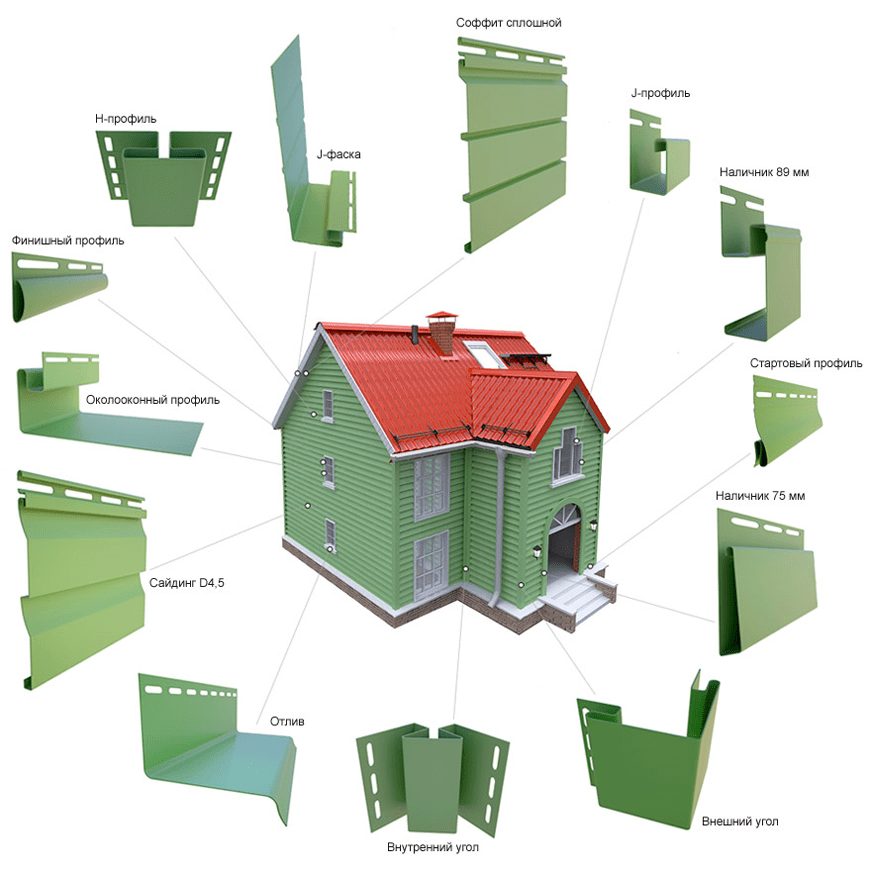

- Siding. It is mounted, like the lining, on the sheathing, but is attached only horizontally, which requires that the sheathing be installed vertically.

Siding can be from:

- Plastic.

- Metal.

- Asbestos cement.

Tip: Plastic or metal should be used for interior lining. Outside – asbestos-cement siding.

The technology is similar to installation plastic lining oriented horizontally:

- The starting profile is installed below.

- Siding plates are inserted.

- The plates are screwed from above to the sheathing with self-tapping screws.

- This technology is repeated all the way to the top: the edge of the top plate is inserted into the groove located on the bottom plate.

Advice: All hanging cladding materials mounted on the sheathing, except metal, cannot be fixed rigidly. A small damping gap should be left around the perimeter of the wall, which will prevent the cladding from deforming during seasonal temperature fluctuations.

- Profiled sheet. The metal thickness is selected from 0.4 - 1.2 mm.

Most often the material is zinc coated. But for the garage it is better to purchase sheets painted with powder paint. Their advantages:

- Beauty.

- Reliability.

- Long service life.

Theoretically, the corrugated sheet can be mounted directly on the wall, but it is better to mount it on the sheathing. In this case, the sheets are fixed with self-tapping screws. The use of rubber or polymer press washers protects the metal from corrosion.

Ceiling finishing

Typically, the ceiling cladding is made with the same materials as the walls, or in harmony with their finish.

For straight and fairly level ceilings in the garage, you can purchase ceiling foam panels, their price is not too high, they wash well, and they are glued to the ceiling quickly and easily. If necessary, such panels can be repainted with water-based emulsion in a different color.

Creating a floor

A strong and reliable floor in the garage means order and cleanliness in the room. It is necessary that flooring:

- Supported the weight of the car.

- It was frost-resistant.

- Easy to clean.

- Withstands mechanical damage.

Along with traditional materials, slag-sitall boards can be used. Their advantages:

- Reliability.

- Strength.

- The beauty of garage flooring, as can be seen in the photo.

You can create a beautiful DIY flooring inside your garage from wear-resistant linoleum of the highest quality. But this will be a rather expensive option. The arrangement of the garage in this case should also be unusual. Read more about the arrangement here.

Arrangement of gates

An important role is played by the finishing of garage doors, which can also be made not quite standard. For example:

- For conventional garage doors, profiled pipes or metal corners. For quick finishing, with minimal cost, you can purchase sheets of foam plastic, the thickness of which is more than 30 mm, and cover the gate with them. To do this, use “Liquid nails” or polyurethane foam, which fills all the gaps. For beauty, the top of the foam is covered with foil penofol, which is insulation and reflects heat into the room.

- Perform interpretation frame cladding. To do this, a wooden frame is attached to a profiled pipe or corner, and then any facing material is sewn onto it. In this case, the insulation is laid inside.

All the nuances of performing non-standard finishing of walls, ceilings, floors and garage doors can be seen in the video. In any case, each owner himself chooses how to arrange a room for a car. The main thing is that it is dry, warm and comfortable not only for the vehicle, but also for its owner.

And what materials are used to make your dream garage, see the video below.

Lining your garage is very important. Cladding is done inside and outside. Of course, it performs several functions at once. The emphasis is on the following:

Today we will take a closer look at the exterior wall decoration. We will find out how to cover the outside of a garage, what materials are most practical and economical. Let's look at the process of covering walls with siding and find out the features of the technology. All useful information, algorithms and tips will help you then carry out all the work yourself and achieve a better result. Then the garage wall cladding will serve you for many years and will successfully perform all its functions.

There is now a fairly wide range of building materials for cladding the walls of the garage from the outside. We will focus on the main ones and pay attention to them key characteristics. The greatest demand is for siding and plaster, as well as lining and artificial stone, and blockhouse. Of course, some garage workers choose brick cladding.

Plaster

The technology is widespread wet facade" This is not just plastering walls. The process will be a little more complicated.

- First of all, the walls are treated with a layer of adhesive.

- Then the polystyrene foam boards are fixed with glue.

- Then everything is carefully covered with glue again.

- In the next step, a special reinforcing mesh is fixed to the walls.

- Already on final stage complete plastering is carried out.

From a technological point of view, the work is somewhat complex, but with certain skills it can be done easily. It is important to follow the sequence, do everything carefully, and monitor the quality of the solutions. Then this finish will last a relatively long time. Basic benefits method - reliability and strength of walls, thermal insulation effect, efficiency. True, in order to ensure decent quality of such a coating, you will have to additionally level the walls before carrying out the work.

Siding

Siding is extremely popular. You can choose metal or cement, wood or vinyl siding. Everything will depend on the personal preferences of the car enthusiast and budget capabilities. The widespread use of vinyl siding, which attracts optimal combination reasonable cost and good technical characteristics. Let's note its advantages.

- Vinyl siding is easy to install.

- It perfectly protects garage walls from moisture.

- Material attracts high level fire safety.

- Experts note the increased resistance of vinyl siding to sudden temperature changes.

- The material is durable, reliable and safe.

- The panels weigh little, which greatly simplifies the process of transportation and installation, and reduces the load on the load-bearing structures of the garage.

Some garage workers opt for wood siding. It certainly requires additional treatment with fire retardants, and is also quite expensive.

Cement siding is not very practical due to a significant drawback - heavy weight. Metal siding is popular. It is very durable, it is not afraid of mold and mildew, and temperature changes. But you will have to take additional care to protect the material from corrosion. It is necessary to use special self-tapping screws with rubberized heads during the installation process.

Block house

An original option for cladding the exterior walls of a garage is a blockhouse. He's the most suitable for those, whose house nearby is also decorated with this material. Then the residential building and garage will form an excellent architectural ensemble. The blockhouse looks elegant and visually imitates log wall. The material is divided into classes. For a garage, you should choose class A coating, which is most suitable in terms of quality and price.

Wooden lining

An interesting solution is to use wooden lining for lining the garage walls. It is produced from coniferous and deciduous trees. This material is distinguished by its environmental friendliness and safety, but requires mandatory additional processing. Here you need to use fire retardants to increase the level of fire safety. Of course, the ease of installation of the lining is also attractive: the elements of the material are immediately equipped with a special locking system based on the tongue-and-groove principle. This is very convenient in the process of fixing the wall covering layer.

The lining is produced in several classes. The highest quality ones have the highest price. You can opt for the optimal option: class A lining has quite decent characteristics and an average cost. It is just perfect for covering a garage.

Natural and artificial stone

Some garage workers choose stone for wall cladding. This material allows you to create a memorable design and turn the building into a work of art. Of course, there are some nuances. During the installation process, dealing with stone is not so easy. It is advisable to have at least minimal builder skills, since the process is labor-intensive: it is important to apply the adhesive composition correctly, to do everything as carefully and competently as possible so that the coating is securely fixed.

You also need to choose whether to use artificial or natural stone. Natural material has better performance characteristics, but it weighs much more and is more expensive. This will require a significant budget, and there will also be a serious load on the walls.

We cover the garage with siding

Garage siding - optimal solution. Let's take a closer look at the process of wall cladding and find out how to make the coating as reliable, durable and aesthetic as possible.

Materials

Of course, you will need the siding itself. You can choose vinyl. Also, immediately think about how you will install the panels. Since the garage space is most often not heated, the best solution in this case, the walls are faced from the outside using a ventilated façade system. Then you will simultaneously carry out thermal insulation. Thermal insulation material is simply placed in the sheathing cells during the installation of a ventilated facade with siding. The internal area will remain free from the insulation layer.

Panel types

It is important to decide on the type of siding panels. It depends on this what configuration of the ventilated façade you will have, what kind of structural elements you will need.

- Horizontal siding is installed horizontally. It perfectly imitates the board profile and wood texture. When installing such siding, the sheathing parts are placed vertically, and the cladding is done from the bottom up. A starting bar is mounted along the lower perimeter, and work begins from there.

- Vertical siding is used less often. By texture and appearance it is similar to the horizontal one, but its configuration is different. Sheathing belts under vertical material made horizontal. The installation is also different. It is carried out from the corners of the building, without laying the starting bar. Work begins with special profile, which is mounted in the corners. It is into its groove that the first and last element is inserted.

- For the above-ground part of the foundation is also presented basement siding, adapted to standard height dimensions. It’s easy to work with, it’s good for finishing basement part garage.

Siding can be metal and vinyl, composite and plastic, cement. A wide range of color solutions is available. The cost largely depends on the raw materials from which the siding is made. Installation of elements fundamental differences does not, but there may be a slight difference in the characteristics of the locking connection. Choose the most suitable option, taking into account individual preferences and the planned budget, but also about technical specifications Do not forget. Vinyl siding remains the most practical.

Cladding frame

We are considering the option of covering the walls with siding using the type of ventilated facade, which immediately ensures insulation of the structure. Let's look at the features of the frame in our case.

You can make a ventilated facade on a wooden or metal frame. If you do insulation, then you should give preference to the combined option. This is what experts and experienced garage workers recommend. Then the lower sheathing is made from bars with parameters 30 by 30 mm, but the upper sheathing must be made from a profile. Think about which option suits you best, and pay attention to the cladding scheme with an insulating layer.

Let's find out why install two battens. The fact is that decorative and thermal insulation materials will differ in size. At the same time, during the installation process, special convenience is created by observing the pitch of the frame belts. It is also important to guarantee a certain thickness of the sheathing so that there is a gap between the cladding and the insulation. It is this distance between the layers, which should be approximately 3-4 cm, that is necessary to create a ventilated façade.

Sometimes garage workers do without the bottom sheathing. They fix the insulation by attaching it to the walls of the garage with dowels, glue mixture. In this case, an indent from the base is still needed. Then it will have to be done using direct hangers. Remember that you will need to glue it with a special insulating tape all joints between insulation boards.

The best solution is to install a lathing under the thermal insulation layer. A step is taken between the profile and the bars, which should be 1 cm less than the width of the slab itself. Then the heat-insulating material will fit well into the cell, and it will be much easier to fix it with glue. You don't even need to hold the slab while the glue dries.

Expanded polystyrene and mineral wool are suitable as insulation. Be sure to pay attention to fire safety: you need non-flammable materials.

The best option for lathing is a metal profile.

You will need a set of tools: a screwdriver and a hammer drill, a marking cord and building level, a screwdriver with a hammer, as well as an electric jigsaw or metal scissors.

Installation of cladding

Let's consider the algorithm for installing siding on the outside of garage walls.

To accurately navigate all the intricacies, it is worth watching the video.

Video: getting to know siding better

Now you can find out even more useful information about siding. It is this material that enjoys increased popularity as the main external cladding garage walls.

This video tells in detail about siding, its main technical characteristics, and advantages.

Have you finally decided to use siding to cover the walls of your garage? It's a good choice. But you will need to understand in more detail how best to install a metal profile under the siding. The following video will help you.

Watch the video carefully. It provides clear installation instructions metal profile under the siding. By following the recommendations, you will achieve reliability and durability of the cladding.

For many car owners, the garage is not only a place to “reside” the vehicle, but also a place for repairs, storage, painting and plumbing work, etc. In an effort to use the room as more than just a box of metal, we think about its finishing. And here the priority is not only high quality materials, but also a low cost of work. To this end, we will look in detail at how to complete the finishing on your own, so that anyone can handle the technology, and the result will not disappoint.

When does a garage need finishing?

Let's look at the conditions under which a garage requires interior finishing, or at least cosmetic repairs.

- You have built or purchased a garage with bare walls or rough finishing, in which you are afraid to even leave your car;

- Are you planning to insulate your garage to maintain a comfortable temperature in it?

- It is necessary to reduce heat loss in a heated garage;

- It is important to you in what conditions the car is stored;

- Are you going to spend most of your time in the garage?

- Do you want to functionally use the space of the room;

- Fire safety of the garage is not ensured;

- Planned renovation of the premises.

Exterior decoration of the garage is necessary:

- To improve the architectural appearance of the building;

- Protection load-bearing structures from environmental influences.

General requirements

The interior decoration of the garage includes the cladding of all surfaces of the room and the installation of floors. Pay special attention to finishing materials. Most often, the garage is subjected to intensive use, chemical and mechanical stress. Therefore, to preserve structures and ensure fire safety, the following requirements are imposed on materials:

- Non-flammability;

- Chemical resistance;

- Not susceptible to absorption of odors, dirt and dust;

- Strength and resistance to mechanical stress, scratches, shocks, etc.;

- Resistance to temperature changes;

- Easy to install and operate.

Interior finishing options: what materials can be used

There are a sufficient number of options for finishing garage walls, ceilings and floors to suit every taste and budget. Here everyone decides for themselves, comparing their desires and capabilities. However, the choice depends not only on the personal preferences of the owner, but also on the material of the enclosing structures themselves.

Walls and ceilings:

- Plastering walls, ceilings;

- Ceramic tile cladding;

- Covering with PVC panels;

- Chipboard cladding;

- Sheathing with plasterboard.

- Concrete floors;

- Floors made of ceramic or paving tiles;

- Self-leveling floors;

- Wooden floors.

Walls and ceilings

- Plastering. Plaster is the most common type of finishing for brick and concrete structures. Cement-sand mixture does not require large financial costs and ensures regulatory fire safety of structures. When painted over plaster, walls and ceilings acquire a finished, neat appearance and a hard, durable coating. It does not absorb odors and is easy to repair. In this case, for the garage it is recommended to use facade plaster or cement based, which is not afraid of moisture and low temperatures.

Minus finishing material is the complexity plastering works, the need for the necessary skills and the presence of construction dirt during work.

After the plaster has dried, it is recommended to putty the ceiling and walls before painting to save paint and varnish materials and smoother application. The putty is applied in 1–2 layers to the surface treated with a primer. Application thickness - up to 3 mm. It is better to carry out the work using a façade mixture or a cement binder.

If putty is not at all part of your plans, painting can also be done on a plastered surface. But be sure to coat the surface with a deep penetration primer before painting, which will not allow the paint to soak into the concrete.

Advice: Plastering should be carried out in the warm season.

Several types of compositions are suitable for painting: epoxy or polyurethane based paints, facade paints.

Plastered and painted walls and ceiling

- Ceramic tiles are perfect for cladding walls and floors in the garage. The advantages of such a coating are, first of all, strength and reliability, aesthetic appearance of the room and easy operation. This surface is easy to clean and repair if minor defects appear.

However, there are some limitations. They cover brick, concrete or aerated concrete surfaces, and thin, light walls will not withstand the considerable weight of the tiles and a layer of adhesive. In this case, minimal vertical deviations are allowed. Obviously, finishing walls and floors with tiles is an expensive pleasure, and time-consuming.

The walls and floor of the garage are covered with ceramic tiles

- Another popular option for finishing walls and ceilings is PVC cladding panels. The material is in demand due to its availability and ease of installation, which almost anyone can handle. It is worth noting that this is a non-flammable and moisture-resistant material. But plastic panels are significantly inferior to other materials in terms of strength and resistance to cold. In this regard, experts recommend using a more expensive option for facade works. In favor of the lining, we add that the frame, which is attached to the walls and ceiling under the panels, is suitable as cells for mineral wool board. This is necessary if the enclosing structures of your garage can only be insulated from the inside.

The walls and ceiling are lined with PVC panels of the same color

- Some people use it as cladding instead of lining. particle boards(chipboard). The installation principle remains the same. But due to the fact that chipboard is flammable and easily absorbs moisture, it is attached to the insulation before facing polyethylene film, which acts as waterproofing, and the slabs are covered with antiseptic impregnations on top.

Chipboard cladding

- GKL slabs. Similarly, you can line the walls and ceiling of the garage with plasterboard slabs. Drywall is a low-flammable material with good strength characteristics. It is attached to the walls and ceiling on a metal frame, in the cells of which insulation is placed. A layer is attached on top of the insulation waterproofing film, and then slabs. This option of cladding with subsequent painting is one of the highest quality and modern, but also the most expensive. Therefore, gypsum boards are more often used for finishing residential premises.

GCR with coloring

Floors

- When it comes to floor coverings, the most common subfloor in garages is painted concrete floors. They can withstand the load of a car and other equipment, are resistant to abrasion, and do not collect dust. When priming the floor with special paint and varnish compounds, it is able to resist the absorption of odors and chemical solutions . Despite the fact that the process of installing a concrete floor is quite lengthy, the low cost and simple technology

make it the most popular.

- Painted concrete floor Tile. Ceramic tile floors look neat and aesthetically pleasing. This coating is easy to clean and does not absorb liquids or odors.

- Self-leveling floor. Another option for impact-resistant coating is self-leveling flooring. This modern solution flooring installations both in residential and non-residential premises, the main advantage of which is ideal Smooth surface. It is not inferior in strength to concrete. Most likely, this material would be a win-win solution for flooring. The result of the work is a smooth coating that does not give way external influences and destruction. But despite all the perfection of the coating, it cannot be called economical due to the high cost of the composition. It is recommended to fill the base with minimal deviations, which is not always possible in a room such as a garage.

Ideal self-leveling floor surface

- Wooden floor. For car enthusiasts who prefer environmentally friendly materials, you can choose wood. In this case, it is not necessary to level the base. But there are more disadvantages of such a floor than advantages: easy flammability, susceptibility to absorption of fuels and lubricants, odors and moisture, low strength characteristics.

The entire interior area of the garage is lined with wooden boards

Which option is better to choose?

Summing up and analyzing the options, from the point of view of practicality, durability, resistance to damage, we advise you to choose concrete floors and plaster as cladding for the internal walls of the garage. This option is appropriate if the walls are made of brick, concrete or aerated concrete. If the work is done well, you will get a decent result with minimal labor and cost. As for walls made of metal profiles, they can be covered with façade PVC panels.

Calculation of material for plastering walls

Anyone can calculate the amount of plaster mixture. Let's say you know the area of the garage walls without taking into account the openings S st in m 2. The main thing is to determine the average layer thickness t sl. To do this, measure the deviation in several places with a two-meter level and calculate its average value.

Manufacturers indicate the consumption of cement plaster on the packaging. On average, this value is 8 kg per 1 m2 with a layer thickness of 10 mm.

Required amount of mixture: N cm = S st x t sl x 8 kg.

Most often, dry plaster mixture is supplied in bags weighing 30 kg. Divide the resulting value N cm by 30 and round the number up. You receive the number of bags needed to plaster the walls.

The required amount of paint N cr also depends on the consumption indicated by the manufacturer on the packaging.

Let's calculate the amount of material in a garage with walls 4.5 m and 3.5 m long and a room height of 2.5 m.

The area of the garage walls is: (4.5 + 3.5) x 2.5 = 40 m 2. Having measured the deviation from the vertical, we obtained the following values: 3.5 cm, 2.5 cm, 1.5 cm, 3 cm.

Average layer thickness: t sl =(3.5+2.5+1.5+3)/4=2.6 cm, rounded to 3 cm (0.03 m).

Amount of mixture: N cm =40x3x8 =960 kg. Number of bags: 960/30=32 pcs.

Epoxy paints for painting walls in 2 layers have a consumption of about 400 g per 1 m2 (0.4 kg/m2).

Amount of paint: N cr =40x0.4=16 kg. Packaging of paints from 5 kg per container and above.

Calculation of materials for flooring

To calculate cement and sand when installing floors, determine the thickness of the required screed. Depending on the base, the presence or absence of insulation, it can vary from 3 cm to 10 cm. The volume of the screed is calculated by multiplying the thickness by the floor area. ¼ of the resulting volume is M400 cement and ¾ of the volume is fine sand. A desirable condition is floor reinforcement. For this we use a wire mesh Ø5 mm with cells 10x10 cm.

The floor area of our garage is determined as: S=4.5x3.5=15.75 m2.

Volume of gravel V gr and sand V pes for a pillow, thickness 20 cm (0.1 m +0.1 m): V gr = 15.75x0.1x1.1 = 1.7 m 3, V pes1 = 15.75x0, 1x1.1=1.7 m3, where 1.1 is the compaction coefficient.

Let's take the screed thickness to be 5 cm. Screed volume: V st =0.05x15.75=0.79 m3. Therefore, the volume of sand: V pes2 = ¾ x 0.79 = 0.6 m 3, the volume of cement: V cem = ¼ x 0.79 = 0.2 m 3. Based on the average cement density of 1300 kg/m 3, we obtain the required weight of cement: N cement = 0.2X1300 = 260 kg.

Amount of paint: Ncr = 15.75x0.4 = 6.3 kg with a material consumption of 400 g per 1 m 2.

Required Tools

- Trowel;

- Half-grater;

- Grater;

- Falcon;

- Rule;

- Steel brush;

- Angle spatula;

- Putty spatula;

- Scraper;

- Shovel;

- Trough;

- Vibrating plate;

- Bars;

- Beacons;

- Roller;

- Brushes.

Floor installation. Step-by-step instruction

The process of installing a concrete garage floor depends on the substrate. If there is an existing concrete slab, then to pour the finishing screed you only need to clear it of dust.

Tip: If water constantly accumulates in the garage, make the floor slope 3%.

When pouring a floor over the ground:

Advice: Pouring concrete should be done without long breaks and in the warm season.

Video instructions for pouring a concrete floor on the ground

How to plaster walls and ceilings with your own hands

Plaster work starts from the ceiling and ends with the walls.

- First, carefully evaluate the surface of the walls and ceiling. Remove all protruding parts and cover the depressions with cement-sand mortar over a previously wetted surface.

- The ceiling is most often reinforced concrete slabs. In the event that you do not strive for ideal surface, installation of beacons is optional, and the joint can be leveled using mortar. The ceiling is plastered with lime, cement and gypsum mortars. Despite the fact that gypsum lays down better and sets faster, they cannot withstand temperature changes. Therefore, in unheated rooms It is recommended to plaster with cement mortar in a cement to sand ratio of 1:3 or 1:4.

- After cleaning the surface, a primer is applied for better adhesion.

- After the primer has dried, the plaster is applied with a spatula or trowel in several layers. Each layer should be 0.5–1 cm, and the next one is applied after the previous one has set. In this case, the total thickness of the plaster should not exceed 1.5 cm, sometimes 3 cm. The first layer is the base layer, which should adhere well to the concrete. The second layer is leveling. The third is finishing, troweling, applied in a circular motion.

- Wall plaster is also applied in 2–4 layers along the beacons. The recommended layer thickness is 3 cm. Beacons set the thickness of the plaster layer. They use metal slats or strips of mortar, aligned with the rule. All beacons are finally adjusted by level. Metal ones are attached to dowels or mortar, and after plastering they are dismantled.

- Clean the surface from dust and debris, moisten the wall with a roller or spray, or coat it with a primer.

- First, the first layer is applied to the wall - spray, which provides adhesion to the surface. After the spray dries, there is a thicker base layer - soil, which is used to level the surface. The plaster is finally rubbed with a covering layer.

- Apply putty in 1-2 layers with a thin spatula to level the surface.

- The primer is made wide brushes and a roller. Be sure to let it dry before applying the next coat.

- Painting is done with a roller and brushes in 2 layers.

Video. Instructions for plastering indoor surfaces

Exterior decoration of the garage. Possible options

There are many types of garage façade finishes. The most popular of them:

- Joint jointing - suitable only for brick walls;

- Plastering and painting;

- Wall covering with siding;

- Wall cladding with wooden clapboard;

- Wall cladding with facade brick or natural stone;

- Wall covering with sandwich panels.

Unstitching. This is the easiest and most inexpensive way to bring your garage into decent shape. The color of the grout mixture can be used darker or lighter than the brick itself, which will add contrast to the walls. In this case, greater strength of the masonry is achieved.

The garage walls are made of colored bricks with beige grout

Plaster. Plastering is inexpensive, but, as with interior decoration, it is a rather long and dirty process. If the quality of the interior finishing is hidden from prying eyes, then plastering the exterior will require experience, skill and patience.

In this case, the walls can be insulated. This facade is called “wet”. The insulation is glued to the wall, then a fiberglass reinforcing mesh is attached to the polymer-cement mortar. Facade or decorative plaster followed by staining.

The walls are plastered and painted

Siding. You can insulate and decorate a garage with the most inexpensive and versatile material - vinyl siding. It does not crack, does not rot, is not subject to deformation in dry and wet weather, has a rich color scheme and looks neat. You need to be meticulous in its installation, but you won’t need any special abilities.

Covering with horizontal siding panels

Wooden lining. For lovers environmental materials the facade can be covered with wooden clapboard. The advantages of this type of finishing are a cozy warm look, a variety of textures and a simple installation process. But wood requires constant antiseptic and fire-retardant treatment, and given the uneconomical nature of this material, such finishing will not be affordable for everyone.

Wooden clapboard garage

Natural or artificial stone. Luxury finishing - garage cladding with natural or artificial stone. The facade looks expensive, beautiful, is not afraid of low and high temperatures, moisture. However, the price is too steep.

Garage walls made of natural stone

Sandwich panels. Cladding with sandwich panels - convenient option to perform two tasks at once: insulation and finishing of the facade. But due to the significant weight of the panels, not every foundation and wall can withstand such a load. Best use the material is found as independent enclosing structures.

Garage walls made of sandwich panels with contrasting profiles

Selecting an exterior finish option

Based on the most important indicators of efficiency and ease of installation for car enthusiasts, we will describe in more detail covering a garage with siding with insulation, as the simplest and most inexpensive way finishing.

The essence of the method is to construct a wooden or metal frame, in the cells of which insulation is laid. A vapor barrier must be installed on top of the insulation. Siding panels are mounted on sheathing built on top of the previous frame.

Consequently, when finishing a facade without insulation, only the sheathing is installed.

The thickness of the insulation, which is suitable for polystyrene foam or polystyrene foam, should be taken within 5 cm. Accordingly, the cross-section of the sheathing strips should be at least 5 cm.

Material calculation

Quantity required siding calculated by dividing the area of all walls, minus openings, by the area of one panel, or by dividing the height of the wall by the height of the siding element.

The length of standard vinyl siding panels is in the range of 2.5–4 m, and the width is 20–30 cm, but in the calculation it is worth using the useful area of the element.

The lathing is calculated provided that the distance between the guides is 0.3–0.5 m.

You will need:

For example, consider a garage with dimensions of 4x5 m in plan. Building height (H) - 2.8 m, gate (hxl) - 2.7x2.5 m.

Garage perimeter: P=(4+5)x2=18 m.

Wall area excluding openings: S st =РхН-hxl=18х2.8–2.7х2.5=43.65m2.

Length of the sheathing in increments of 0.5 m under the insulation: L arr =P/0.5xH+H/0.5xP=18/0.5x2.8+2.8/0.5x18=126 m. Number of stands instead of the sheathing: N under =3xS st =3*43.65=131 pcs.

Volume of a mineral wool slab 5 cm thick: V ut = 43.65 * 0.05 = 2.18 m 3.

Vapor barrier: S steam = S st = 43.65 m 2.

When facing with siding, we use panels 4 m long and a useful height of 0.19 m. To cover walls 5 m long, we cut additional meter-long elements from the main profile.

Required number of whole panels: N 4 = 4x2.8/0.19 = 59 pcs.

Number of shortened meter elements: N 1 = 2x2.8/0.19 = 29.4 pcs.

Panels 4 m long for cutting meter pieces: N 4/1 = 29.4/4 = 7.4 pcs.

Total number of four-meter siding elements: N pan =59+7.4+7%≈71 pcs., where 7% is a reserve for waste, etc.

Quantity of H-profile: N H-pr = 2 pcs.

Starting and finishing panels: N st =N fin =P/4=18/4=4.5≈5 pcs.

Number of corner panels: N corner =2.8x4/4=2.8≈3 pcs.

Quantity of J-profile: N J-pr =(2.7x2+2.5)/4=1.9≈2 pcs.

Self-tapping screws for fastening siding: N itself = 20x43.65 = 873 pcs.

Tools

- Knife or saw for metal;

- Level;

- Sander;

- Scissors for cutting metal;

- A punch that will be needed to punch out “ears” along the edges of the siding panels;

- Hammer;

- Screwdriver;

- Dismantling accessories;

- Hammer;

- Pliers;

- A tape measure at least 8 meters long;

- Construction rope and pencil;

- Construction stapler.

How to cover walls with siding and insulation

- Clean the surface of the walls from dust and dirt and remove all protruding elements.

- Installation of sheathing for insulation. The frame is attached in increments of 40–50 cm using a screwdriver, self-tapping screws or nails, depending on the condition of the surface. To save money, instead of the sheathing, you can install wooden or metal stands on which the insulation is placed.

- Sliced roll insulation required sizes, inserted into cells or mounted on stands.

- The vapor barrier is attached with a construction stapler.

- Mounted metal or wooden sheathing. When installing siding panels horizontally, sheathing slats can only be attached vertically.

- Installation of guides. By external and internal corners buildings, corner panels are installed and rigidly attached to the wall. A base panel with ebb is mounted on the plinth, and a starting panel is installed above it. In this case, the fastening of the panels to the wall should be loosened, which will prevent their deformation. To do this, leave a gap of 1 mm between the screw head and the panel. We attach the guide elements with an overlap of 2.5 cm.

- If there are openings, we install platbands around the perimeter, starting from the bottom. Don't forget about the tides.

- Install the remaining panels, moving from bottom to top. Fastening is also carried out with a gap and without overlap. We complete the siding installation with the last finishing strip under the roof.

Setting up your favorite garage can take a huge amount of money and time, because you can’t get by with just one specialist, and you need control over everything. The question arises: is the finishing worth it? utility room financial and labor costs? Our answer: it’s definitely worth it, if you approach it wisely and do the full range of work yourself. By performing work conscientiously according to the recommended technology, you will not only save money, but create cozy space By at will and the project, while gaining invaluable experience and recognition from households and neighbors.

Hello! My name is Kireeva Ekaterina. I am 29 years old. Graduated from the Construction Institute as part of State University Togliatti in 2008 in the direction of "Industrial and civil construction". She is well acquainted with construction and production. Thanks to this, articles on construction topics are very close to me.