Fence made of brick and metal profile. Construction of a combined fence made of brick and corrugated board. Fencing design and material

Corrugated fence with brick pillars They are highly durable and reliably protect the area from the penetration of uninvited guests and animals, and brick pillars give such a fence a very rich and aesthetic appearance. When building fences for a summer residence, corrugated sheeting with a colored polymer coating (polyester) is usually used. It provides excellent corrosion resistance installed fencing, attractive appearance and color schemes according to general concept design of the house and plot. The primer and polymer coating are applied to the corrugated fence by the manufacturer. The brick pillars themselves can be laid out of facing bricks different colors and texture, clinker and ordinary building bricks. Next, such a pillar can be covered decorative plaster or cover it with decorative stone.

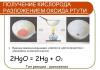

Advantages of a fence made of corrugated sheets

with brick pillars

- Reliability A fence made of corrugated sheets with brick pillars is a reliable barrier against thieves, unnecessary noise and prying eyes, as well as negative impact external environment.

- Practicality Profile sheets have a polymer coating that protects the sheet from corrosion, is easy to clean from dust and dirt, and can be easily replaced if damaged.

- Durability Fences made of corrugated sheets with brick pillars have excellent resistance to corrosion and other external influences.

- Aesthetics Combination of profile sheets with pillars made of natural brick or stone, gives the fence a very rich and aesthetic appearance, visually ennobling the area.

Materials and components for the construction of corrugated fences with brick pillars

- Types of bricks

- Profile types

- Color palette

- Pillar decor

- Caps

Profiled sheet S-20

A beautiful type of corrugated board for a fence. Has significantly greater section rigidity. It can be used in a thickness of 0.35-0.5 mm, especially when adding additional logs.

Profiled sheet HC-8

The most rigid corrugated sheeting for a fence. When using such a profile, you can increase the spans between pillars and reduce the number of logs. Such a profiled sheet can be installed horizontally without crossbars at all. Such corrugated sheeting can be used in a thickness of 0.32-0.35 mm, especially when using additional logs.Facing brick  Clinker brick

Clinker brick

Cost of a corrugated fence with brick pillars

The procedure for installing a fence made of corrugated board on brick pillars

- 01

Marking

plotWhen marking the site, we use a level, tape measure, pegs and string. At this stage of fence construction, pegs are placed at the border of the site, under the entrance group, as well as marking the levels of the foundation and brick pillars when there is a difference in the relief of the site.

- 02

Arrangement

foundationAt this stage we are digging a trench for the future strip foundation and separately make a foundation for each brick pillar. Then we install formwork made of laminated plywood, add a sand cushion, lay a frame made of reinforcement and fill everything with concrete grade M200-M300, followed by vibratory compaction.

- 03

Brickwork

pillarsAt this stage, the brick pillars are laid. Bricks are laid out around metal pole 1.5 bricks wide. Thus, the column turns out to be 380x380 mm in size. When laying into a pillar, metal embedded elements from the corner are laid in advance. The internal cavity is filled cement mortar. After masonry, the masonry joints are jointed to seal and give the seams a beautiful appearance.

- 04

Installation of decorative elements

The tops of the brick pillars are crowned with decorative caps made of sheet metal in the same color as the corrugated sheet, or cast from concrete or alabaster. A metal casting of the same color as the corrugated sheeting is installed on the surface of the foundation.

- 05

Installation of metal frame and corrugated sheets

At this stage, horizontal crossbars are welded to the brick pillars, to the pre-exposed mortgages. Places welds are cleaned and treated with primer or paint, which provides anti-corrosion protection fencing. Sheets of corrugated sheets are attached to the logs, overlapping one wave, using metal screws in every second wave.

- 06

Gate installation

and wicketsAfter installing the corrugated sheeting, we proceed to installing gates and gates. To do this, racks with hinges and also wicket recesses are welded to the protruding embedded elements of the brick pillars. The frames of gates and gates must fit into the opening very accurately, with a gap of no more than 10 mm. Gates and wickets are equipped with all necessary locking hardware.

Why our company

- High quality Thanks to our own production, the use of high-quality materials and professional equipment, we always achieve high quality.

- 2-year warranty Thanks to our own production, the use of high-quality materials and professional equipment, we always achieve high quality.

- Competitive prices Since we work closely with domestic suppliers who provide us with discounts, we are able to support affordable prices on fences made of corrugated board under a tree.

- Stable budget After we have compiled budget plan and we will agree it with you, the final amount will be approved. This means that there will no longer be any additional costs included in the estimate.

- Delivery of materials Our teams are fully staffed. We cover all costs for delivery of materials to your site. All you have to do is call and order fence installation.

- Convenient options payment Our company provides various options payment. You can pay us directly at the site or through any Bank of Moscow office using a bank card.

- Manager's visit We can organize a team visit to your site at a time convenient for you. At the site you will be able to sign an agreement, after which our specialists will begin fulfilling the order.

- We do it thoughtfully and responsibly.

Quickly, but carefully,

smooth, beautiful.

By ordering a fence made of corrugated board with brick pillars you will receive

When ordering the construction and installation of a fence made of corrugated board with brick pillars in our company, you will receive a guarantee certificate that will confirm not only the quality of the work performed, but also our legal liability. Consequently, we will provide you with post-warranty service for the installed fencing for two years.

Order the construction of a fence from corrugated sheets with a 2-year guarantee

Corrugated fences have recently become increasingly popular. This aesthetically attractive material is relatively cheap, which allows you to build strong fencing for a summer residence for a relatively small amount.

There are several options for making such fences, but a fence made of corrugated sheets with brick pillars is especially beautiful and reliable.

There are several options for making such fences, but especially with brick pillars, which every owner can build with his own hands.

Choosing corrugated board for the fence

Sheets of corrugated sheets have different purposes: roofing, for load-bearing structures, for finishing facades.

Sheets of corrugated sheets have different purposes: roofing, for load-bearing structures, for finishing facades. To build with your own hands reliable fence for a dacha, you should buy a profiled wall sheet. Its prices are minimal, and the quality of the material allows you to get a strong and durable fence. The coating of the sheet is important. You should not purchase material without polymer painting, since without this protective layer rust stains will soon appear on the fence. Uncoated copper or aluminum corrugated sheets are not subject to corrosion, but the cost of this material is quite high. That's why the best option will use a galvanized profile or sheet with a polymer colored coating in the construction of a fence for a dacha.

Its thickness plays a big role. This is an indicator of the material’s resistance to adverse influences. environment And mechanical damage. The smaller the thickness, the lower the price of the metal profile. In order for the fence to last for many years and not require annual seasonal repairs, you should buy sheets with a thickness of at least 0.6 mm. If you focus on the brand of corrugated sheeting, then C8, C10, C13, C18 and C21 meet these requirements. Each owner chooses a color scheme in accordance with his preferences. You should also pay attention to the thickness polymer coating. The larger it is, the less chips there will be and the need to touch up scratches and other flaws.

Construction of a foundation for a fence with brick pillars

Most often, MZL is erected - a shallow strip foundation. It's easy to do it yourself.

for a dacha - a special structure. It requires a monolithic strip foundation. Most often, MZL is erected - a shallow strip foundation. It's easy to do it yourself. This base for the pillars is located above the freezing point of the soil and is a continuous concrete line along the entire perimeter of the fence.

Stages of construction of the MZL

- The site is being marked. Pegs are placed at corner points by hand and a cord is pulled between them.

- The width of the tape should correspond to the thickness of the brick pillar that will be installed on it. But you can choose a more economical option: make the tape wider under the pillars, and narrower under the spans of corrugated sheets. All parameters of the future fence must be foreseen and calculated in advance.

- A trench is dug along the marking lines. Its depth must be at least 70 cm. The bottom of the ditch must be compacted. To do this, make a simple device: wooden block required length, to which the handles are nailed.

- The next stage is pouring a sand cushion 20 cm high. It should be watered and compacted thoroughly. The purpose of the cushion is to prevent deformation of the foundation when it freezes.

Reinforcement of concrete tape

- Reinforcement plays an important role in the design of MZL. The reinforcement must be connected to each other using wire and laid in two layers. In this case, the foundation will be durable. It is best to assemble the reinforcing frame on the ground, and lower it into the trench after installing the formwork.

- If the area of the dacha has a slope or large differences in height, then making a concrete strip of the same height level will be too expensive and labor-intensive. Therefore, it is best to make a stepped base that repeats the features of the relief at regular intervals. In this case, the reinforcing structures of each “step” cannot be connected to each other, as this will lead to deformation of the foundation during freezing of the soil.

Installation of formwork for the plinth

- We build the formwork with our own hands: the height of the plinth is chosen by the owner of the site independently, but it must be at least 10 cm. If the foundation is stepped, then the formwork must follow its shape. Semi-edged boards are used as a building material. They should be reinforced with lintels, since the concrete pressure will be high.

- When the formwork is installed and the reinforcement frame is lowered into the trench, pipes or corners are installed in the places where the brick pillars are erected. This will strengthen the design of future brick supports.

Preparation and pouring of concrete

- The concrete mixer should be installed in such a way that the solution from the neck pours directly into the trench.

- Composition of the solution: 1 part M400 cement, 3 parts sand, 6 parts medium crushed stone, 0.7 parts water.

- To increase the frost resistance and plasticity of concrete, special additives are added to it. But you can improve the quality of the solution and quite in a simple way: Add 10 ml of liquid soap to a bucket of water.

- After pouring the foundation, the concrete is covered plastic film. Further work can begin no earlier than in 2-3 days.

If you decide to prepare the solution manually, then the sequence of adding the ingredients will be different:

- A bucket of cement and 3 buckets of sand are poured into a container of at least 100 liters. The mixture is thoroughly mixed with a shovel.

- Pours into an empty bucket the right quantity liquid soap and filled with water from a hose. It is advisable to ensure that there is as much as possible soap suds. Then the water is poured into a container with sand and cement. Everything is thoroughly mixed.

- 6 buckets of crushed stone are laid, and the mixture is thoroughly mixed again.

Installation of a metal frame for a fence made of corrugated board with brick pillars

Construction of brick pillars

The erection of the pillars takes place one at a time: in one working day, each of them can be built 0.5 m deep.

In order to build the pillars, you will need facing brick. This work can be done with your own hands, but it is advisable to involve an assistant, since with him the speed of erecting supports will increase significantly. You should decide in advance on the height and dimensions of the brick pillars. Most often they are made 2-2.5 m high in 1.5 bricks. Pillars are built around pipes or corners pre-installed in the formwork.

For bricklaying, a 1:3 cement mortar is used, where 1 part M400 cement and 3 parts sand. The erection of the pillars takes place one at a time: in one working day, each of them can be built 0.5 m deep. The gaps between the pipe (corner) and the bricks are filled with cement mortar. Each row of masonry is reinforced with reinforcing masonry tape 50*50*4. A cap (lid) is installed on each brick pillar, which is more expressive and will give the entire structure a finished look. In addition, the covers will serve to protect the supports from water.

Do-it-yourself installation of corrugated sheets

To fasten the profiled sheet, it is best to use roofing screws with the same color coating as the metal profile.

You need to place sheets of cardboard on the concrete tape so that during installation you do not damage the bottom edge of the corrugated sheet. To make the fence beautiful and neat, we mark the attachment points in advance with a marker. For this purpose, it is best to use roofing screws with the same color coating as the metal profile. The sheets are joined by overlapping one wave. A drill or screwdriver should be used at low speeds so as not to overtighten the screws, otherwise the corrugated sheet will be deformed and dents will remain on it. In addition, when operating at high speeds, the cutting edge of the screws heats up and grinds down. After the installation of the corrugated brick sheet is completed, it will be ready.

With a combination of “brick and corrugated sheeting”. And this is quite logical.

This solution for cottages harmonizes perfectly with any landscape design and architectural style. The creation of such a fence will also bring economic benefits. And the result will be long lasting if everything is done correctly.

Where do they start?

Corrugated sheets are purchased. They are made of steel. Covers them protective layer against corrosion: colored polymer or galvanization.

The advantages of this material:

- High reliability.

- Good strength and elasticity.

- If the sheet is damaged, it can easily be replaced with an analogue.

- 25-30 years of service.

- Powerful resistance to ultraviolet radiation, thermal shocks, natural and mechanical influences.

- Good color range.

Fence with brick pillars. The highlight is that the corrugated board is decorated to resemble a brick.

Installation process

Fences with the specified combination are installed very quickly, since this material is of relatively low mass. There is no need for special equipment here. are powerful reinforcements for the fence. And it will be extremely difficult for villains to climb over such a fence and get past its sharp edges.

Attach the corrugated sheet to the combined fence You can use one of these methods:

- Sheets cover the entire structure

- The sheets are located between the pillars.

The second method is most often used.

Here's how to do everything step by step:

- Choice of corrugated sheets.

- Perimeter calculations.

- Work on the foundation.

- Creating columns.

- Installation of corrugated sheets.

Choosing hardware according to the rules

You must choose taking into account the following criteria:

- Coating: polyvinyl chloride or painting. The first option creates a thick and very durable outer layer. Type of invoice: smooth and unsmooth. Such sheets are powerfully protected from corrosion and other negative factors, but after 2-3 years they fade. The second option is determined by the dyeing agents used. Modern varnishes and paints can create good protection and interesting color implementations.

- The protective layer should be on both sides of the sheet.

- The selection of colors matches the color scheme of the house facades.

- Sheet thickness – at least 5 mm.

- The height of the profile reaches the following parameters: C10 – C8.

Some color examples of the material:

Perimeter calculations

A construction zone is designated. Pegs are placed at the positions of the future corners of the fence. A thread is stretched over them (it is better to take a strong nylon type). Take a tape measure and measure the distance of the pegs from each other. A draft of the intended design is drawn up. The thickness of future pillars is taken into account. The most economical option is considered to be: The thickness of the side is 1 brick, the front is 1.5 bricks. To strengthen the pillar, they use profile pipes. Their parameters: 4 x 4 x 0.2 cm. Every second masonry line is reinforced. For this purpose, a special galvanized steel mesh. Its parameters: 2.5 x 2.5 x 0.1 cm. Here is an example:

If you need to mount a gate, you need to use pillars with embedded components. They must be reinforced with a steel pipe 8 x 0.28 cm.

Land works

Before erecting the fence, you need to dig trenches. In this case, a large volume of excavated soil is formed, about 3 cubic meters. It is better to place it in special bags (40-50 kg) and take it away.

For earthworks here you need two shovels: a shovel and a bayonet, as well as a crowbar.

You can dig a trench, working together, in 4-6 hours, taking into account pauses.

Formwork can be created immediately after digging the trench. An example of high-quality formwork:

For the foundation, formwork can be made only for the basement component, that is, 10-20 cm below the surface level of the ground. The walls of the formwork are created from construction semi-edged boards.

Assembly is carried out using the following tools: electric drill, wood screws.

Advice! It is important to take into account the high effect of concrete on the formwork.

Therefore, to fasten the boards you will need wooden lintels and brick supports. They are introduced only before the foundation is poured. It will be extremely difficult to fix anything later.

- Collect shields while in the trench.

- It starts with the board itself. It is arranged along a thread stretched between stakes.

- To strengthen the foundation, use reinforcing bars 1 cm thick.

- Place vertical rods every one and a half meters in the trench.

- The foundation must be reinforced horizontally with the same rods. They are laid out on both sides at a distance of 10 cm, rising along the trench.

- On both sides they must be laid 5 cm from the concrete surface.

- The reinforcing frame is assembled on the surface. And in finished form placed in formwork.

To fasten the rods you need annealed wire. Its diameter is 1 mm. After introducing the frame into the formwork, reinforcing elements can be mounted there: a corner or a pipe. Level them and secure them with boards.

Example:

Foundation work

Its suitable type is strip reinforced concrete. The width of the base corresponds to the width of the pillars. If discrepancies are found in the foundation levels, then it is necessary to divide the base tape into separate sections. Each level is at least 10 cm.

The depth of the foundation for the planned pillars is equal to the depth of soil freezing in a given geographical area. In the above example, this value is 1 m. In areas under corrugated sheeting, the depth of the base can be reduced to 50 cm.

To create resistance to soil heaving, the shape of the foundation must be expanded towards the bottom of the pit. This will extend the life of your fence.

Activities with concrete composition

To create a high-quality composition, you need a concrete mixer. It is placed near the formwork.

The algorithm for mixing concrete here is as follows:

- The concrete mixer is placed at an angle of 35-45 degrees, covered with crushed stone (6 parts). Crushed stone is an excellent filler and prevents cement from sticking to sand and walls.

- The composition includes: an additive for air entrainment (about.1%), water (0.7 shares) and sand (3 shares). Sand is poured only after the crushed stone is mixed with water. Mixing duration is 30 seconds.

- The angle of the concrete mixer changes to 60-70 degrees. This will prevent dry sand and cement from sticking to the walls.

- Cement (grade PTs-400) and the rest of the sand are introduced.

- The angle of the concrete mixer returns to its initial values. The remaining water should be added.

- Mix thoroughly until there are no lumps.

- Unloading a concrete mixer.

The given proportions are calculated from 1 part of cement. Instead of an additive, you can introduce liquid soap. Its proportion: 10 ml per 12 l. cement. This way you will give the foundation strong stability to frost.

After pouring, immediately cover the concrete with polyethylene. Concrete surface should not dry out quickly.

In hot weather, complete removal of formwork is carried out in about a week.

Creating brick pillars

For this purpose it is usually used facing brick, for example “Bassoon”. The brick is placed on a cement-sand composition.

Composition proportions: 1 share of cement and 3 - other components. For plasticity, you can introduce liquid soap.

In one day, it is optimal to lay out 50 cm of masonry (in height).

In parallel with the masonry, it is necessary to fill the space between the brick and the steel column with the same composition. All rows are strengthened (reinforced) with a special mesh. Its parameters: 5 x 5 x 0.4 cm.

The required distance between the pillars is no more than 3 meters. Their height is affected by: the design of the site, the appearance of the fence, wind load, and the height of the corrugated board.

Masonry pattern:

This material is fixed in the masonry using embedded plates and corners. Their positions are: middle, bottom and top of the columns.

The usual length of sheets is 3 m. And to securely fasten them together, you can use only logs.

After the pillars are erected, protective covers (caps) are attached to them. The caps also give the pillars a complete look.

If you choose concrete caps, it is better to take versions painted with mineral dye. The paint will not wash off from them in difficult weather conditions, and the top layer will not fade. Concrete options placed on top of the posts on a cement-sand composition.

For your information, steel analogues are attached with dowels from below to the brick.

Creating a steel frame

It begins 2-3 days from the moment the formwork is filled with concrete. For assembly you need a profile pipe 2 x 4 x 0.2 cm. They must be welded using the manual arc method. The corrugated sheet is then mounted to the frame.

Frame template (correct pipe positions):

Assembly algorithm:

- Profile pipes are cut into the required lengths. The position of these segments is vertical.

- They indicate the places where the pipe will be welded. From each edge of the fence you need to keep a reserve of 30 cm.

- At the designated points, the pipes are already held in a horizontal position by welding. The grip is on one side only. Here it is better to work with an assistant.

- Checking the correct position of the pipes. Need a level.

- Final welding of pipes in a horizontal position.

Advice! For such welding, equipment with a parameter of 6500 W is better suited.

The welded frame should be covered protective composition And alkyd enamel, for example PF-115.

Installation of corrugated sheets

Scheme:

Before this stage, the foundation is covered with cardboard. This way there is less chance of damage to the bottom edge of the corrugated sheet.

Installation plan:

- Marks are made to place the screws. Need a marker.

- The corrugated sheet is attached to the profile pipe (2 x 4 x 0.2 cm) at the bottom of the corrugation. You need to follow through one wave. Here you need galvanized roofing screws with rubber gaskets. Their parameters: 0.48 x 3 cm. To mount 1 meter of corrugated sheeting you need 6 of these screws.

Type of connection - overlap. To screw in self-tapping screws, you should use an electric drill at modest speeds. This will prevent the cutting plane of the screw from overheating and grinding down.

Price factors

Such fences take about a couple of weeks to create. And this does not take into account possible pauses in work.

Costs here can reach up to 50,000 rubles. Calculation for 6 pillars and a nine-meter fence. But it's cheaper than brick fence with forging elements.

To correctly calculate costs, divide the length of the fence by the length of the selected material (corrugated sheeting).

It is also worth considering the costs of creating concrete composition, reinforcing elements, fasteners, pipes and tools.

Bottom line

Such fences are often built on their own. The issue is not only price, but also quality. It happens that owners do not trust some of the processes to unfamiliar employees. In any case, when people build, pour and install something for themselves, the result is pleasing to the eye, and their soul is much calmer.

How to do it with one hand?

The best option for fencing private households is a fence made of corrugated board with brick pillars. This decision in the choice of building materials is relevant for any site, be it country house or dacha. A well-built fence made of brick and corrugated sheets is an integral part of the overall landscape design estates.

Exterior view of a fence made of corrugated sheets on brick pillars

A fencing structure with brick pillars and corrugated sheet filling has a number of undeniable advantages:

- such a combination of materials allows not only to reduce construction costs, but also to significantly improve the aesthetic characteristics of the fencing structure itself, which harmoniously fits into the surrounding landscape and looks good against the background of any building;

- profiled steel sheets are reliable, durable, and able to withstand wind and mechanical loads;

- due to the presence of a protective polymer layer, corrugated sheeting is highly resistant to ultraviolet radiation and corrosion;

- great variety color solutions, which makes it possible to select materials to match the appearance of the building, in particular for the roof and other elements present in the garden area;

- light weight of the structure, due to which there is no need to build a powerful foundation;

- the ability to quickly replace damaged profiled sheets;

- durability - the operational period can vary from 25 to 50 years, depending on the correct installation and climatic conditions.

The advantage also lies in the ease of installation and the possibility self-execution works Thanks to the brick pillars, the structure acquires originality and solidity.

Design features

Scheme of a classic fence made of corrugated sheets and bricks

IN classic version between the support posts there are sections made of corrugated sheets, which are attached to the logs made of metal corner or profile pipe. For large distances between supports, reinforcement of the entire structure is required. Not only intermediate posts, but also extra row lag or stiffeners, which are located diagonally and are welded to the back side of the filling. The corrugated sheet is placed between the pillars in two options - a small gap is left or the gap is completely filled. The fence must have a base.

Do-it-yourself corrugated fence with brick pillars

When erecting a fence with pillars made of brick and corrugated board, it is necessary to adhere to technology at all stages of construction, which is the main condition for its durability and reliability. Installation work are performed in stages, so each procedure should be considered separately.

Preparatory stage

Before you start building a fence from brick and corrugated board with your own hands, you need to create a project or sketch on the basis of which calculations of the amount of building materials will be made. Unable to develop optimal project excluding landscape features plot. Thanks to having a plan, the amount of work is evenly distributed and the deadlines for their completion are pre-set.

One of the fence design options

On preparatory stage are determined:

- type of soil, on which the depth of the foundation depends;

- the gap between spans - the distance varies from 250 to 700 cm. This indicator directly depends on the characteristics of the site (flat or sloping terrain);

- fence height may be various parameters- from 180 to 300 cm (when choosing corrugated sheeting, it is necessary to take into account the wind load);

- dimensions of wickets and gates;

- type of foundation - on sloping terrain a strip foundation is used; on a flat area it is enough to make recesses only for brick pillars;

- the number of logs located horizontally - with a corrugated sheet height of up to 170 cm, 2 rows are provided, over 180 cm - 3 rows;

- the use of decorative elements in the form upper slats and caps for poles.

Before you build a brick fence with corrugated sheets yourself, you need to prepare building materials in the appropriate quantity:

- profiled sheets (when choosing a material, the height, thickness and working width of the sheets are taken into account);

- metal pipes with a section of 40x40 or 80x80 mm - for intermediate columns (the underground column is added to the length of the upper part, which is from 80 to 100 mm);

- profile pipes with a cross section of 20x40 mm, used for horizontal logs (the width of the supports is subtracted from the total length of the fence and multiplied by the number of rows 2 or 3);

- facing or decorative brick- for the construction of support pillars (calculation is made depending on the size of the stone and rows);

- primer and paint used for processing metal pipes and joists;

- edged board 30 mm thick - to create formwork for the base;

- reinforcement 8-10 mm from which the frame is created;

- reinforcing mesh used in masonry.

For cooking concrete mixture a grade of at least M300 and a solution will require cement, sand, crushed stone and water.

Foundation arrangement

Foundation for fencing made of corrugated sheets on brick pillars

Installation of the fence begins with markings for the strip foundation and supports. Excavation is carried out to a certain width and depth, which depends on the type of soil and the expected load. At the bottom of the trench is created sand cushion thickness of at least 10 cm. In an area with loose soil it is not necessary to install wooden boards to the entire depth, it is enough to place the boards under the formwork only on the ground part.

The strip foundation for the fence is 25–30 cm wide, 50–60 cm deep and rises 30–50 cm above the surface. Optimal parameters the holes for the brick support are 35x35x100 cm, but the depth is selected individually, as it completely depends on the type of soil. Concrete is poured after:

- formwork will be installed;

- a rectangular-shaped reinforcing frame was created;

- support posts are placed using building level.

Complete hardening of the concrete mixture requires a certain time, which varies from 3 to 10 days depending on weather conditions and air temperature. After removal wooden elements support pillars are formed.

The base can be made in the form of a plinth made of facing stone in 2–5 rows. This method involves protecting the base from foundation moisture by creating waterproofing. To do this, a blind area no more than 80 cm wide is made, which will protect the base from getting wet and give a complete finish. appearance throughout the building.

Construction of brick supports

Types of brick supports

The formation of brick pillars is done in two ways: 1.5 or 2 bricks. Depending on the chosen material they will differ in size. The one and a half column has parameters of 38x38 cm. With two stones, the dimensions of the support post are 51x51 cm. The larger the cross-section of the pipe being installed, the smaller remains free space, which is gradually filled with mortar and crushed stone as masonry work is completed. At the height of the horizontal logs, metal embedded elements are inserted into the masonry, to which sections of corrugated sheeting will subsequently be attached or welded.

The support must be exactly level.

In order to give brick pillars increased strength, metal pipes are reinforced with 10x10 mm steel rods or a reinforcing mesh is laid every 3-4 rows. In this case, the thickness of the rod is slightly smaller compared to what was used when arranging the foundation.

Control of the location of vertical and horizontal rows of facing stone is carried out using a plumb line and a building level. Often, such a guide is metal strips that are placed along the perimeter of the support being built, through which the thickness of the mortar layer is adjusted, which allows you to make the dressing seams neat. Planks are used for each subsequent row.

If you do not have the skills to build columns, then it is better to use the services of specialists. In order to save money and in the absence of the possibility of installing full-fledged brick supports, you can make an imitation of brick from special panels. Attached decorative elements to metal joists.

Installation of corrugated sheets

When building a fence with brick supports, the corrugated sheeting is fastened to horizontal logs, which are attached to metal mortgages by welding. To prevent sparks from damaging the surface of the facing stone, it is recommended to use roofing felt or thick cardboard as protection. For protection metal elements from the impact of negative atmospheric influences and corrosion, the surface is treated with primer and paint.

Installation of corrugated sheets

Sheets of corrugated sheets are attached to the profile pipe with self-tapping screws equipped with rubber gaskets, using a screwdriver/electric drill or special rivets. In the lower part, self-tapping screws are located through each wave, and the sheets are overlapped.

Price of a corrugated fence with brick pillars

Determining the price for a fence made of corrugated sheets with brick pillars depends on several factors:

- installation difficulties;

- type of foundation and profiled sheet;

- quantity of materials used;

- independent construction or hiring specialists.

For those who decide to self-installation fence with brick pillars and profiled sheets, a video with a step-by-step implementation of the entire process is provided to help

Every owner own home wants to fence off its territory from curious neighbors and animals from entering the area. To do this, a reliable fence is installed around the perimeter of the site.

Today there are many options for fencing a site, but recently a fence made of corrugated sheets with brick posts has become increasingly common. This fence looks solid and very attractive, unlike other types of fencing. Building such a fence is not particularly difficult, and the financial costs for its installation are low.

Construction of a fence from profiled sheets with brick pillars It is practically no different from building a fence made of corrugated sheets with posts made of metal pipes, but there are still some nuances. First of all, the owner must clearly understand the final version of the fence and calculate its dimensions.

You will also need to prepare necessary tool for work and purchase building materials.

The construction of such a fence includes the following stages:

- preparatory work;

- determining the size of the fence;

- construction of the foundation;

- frame installation;

- laying brick pillars;

- fastening the corrugated sheet to the frame.

Determining the size of the future fence

First of all, it is necessary to determine the size and location of the fence made of corrugated sheets with brick columns. First, the corners of the future fence are marked with pegs and a nylon thread is stretched between them. The length of the perimeter of one side of the site is divided into equal segments. Each marked place is indicated by a peg. In the future, support posts will be installed in the marked places.

Important! Brick columns should not be too wide, so their width on the side and front sides is only 1.5 bricks. If there is a sufficient amount of material, the masonry can be made in two bricks.

The width of the strip foundation should be 20-25 cm. The foundation will protect the territory from penetration by digging under the fence of animals. Typically, the height of the base is 10-25 cm. In some cases, sidewalk curbs are used instead of building a foundation. But it all depends on the preferences of the owner.

Construction of the foundation

To build a fence made of corrugated sheets with brick pillars, a strip foundation is used, the manufacture of which consists of the following steps:

- trench preparation;

- installation of formwork;

- pouring the foundation.

Preparing the trench

By general rule The depth of the trench must be greater than the freezing depth of the soil. As a rule, a trench is dug 40-80 cm deep, depending on the climatic conditions of the area. In the places marked with pegs under the posts, holes are dug or drilled for installing the pipe. The bottom of the wells is compacted with sand and the base of the column is inserted - round or square pipe. Depending on the height of the fence, a pipe of appropriate length is selected.

In progress earthworks a sufficient amount of soil is formed. The top fertile layer can be left on the site, and the rest of the sand is leveled along the fence or transported outside the site.

Important! When installing support posts, you must ensure that they are installed strictly vertically. You can check this with a building level.

Installation of formwork

The height of the formwork is chosen at the discretion of the owner, but making it more than 25 cm above the ground level is impractical. The formwork is erected from semi-edged construction boards. If there is ready-made formwork, install it. To prevent the boards from bending under the weight of concrete, they are additionally fastened with wooden jumpers or pegs driven into the ground.

After installing the formwork, it is reinforced. For this, reinforcement rods are used, the diameter of which is 1 cm. The reinforcing rods are connected to each other with knitting wire, which will increase the strength of the foundation being built. Sometimes the reinforcement cage is assembled from the outside and then lowered into the formwork.

Metal support pillars necessary to strengthen brick pillars. Optimal distance between pillars - 2 meters. To ensure that the pipes do not become askew during the process of pouring the foundation, they must be carefully secured in the well. To check the installation level of the pillars, a nylon thread is also pulled in the middle and on top, similar to the bottom one (which determines the height of the foundation). While pouring concrete, the verticality of the pillars is constantly monitored.

As a rule, the height of the fence is 1.5 meters. Consequently, metal pipes for pillars, taking into account their deepening, should have a length of 1.9 meters.

Pouring formwork

To prepare cement mortar, crushed stone, sand, water and cement are used, preferably grade M 400. In some cases, a plasticizing additive is added to the mortar to increase frost resistance. The ratio of sand and cement in the solution can be 1 to 3 or 1 to 4. It all depends on the brand of cement. The solution is mixed in a concrete mixer or manually until a homogeneous mass is obtained. Household liquid soap (plasticizing additive) is mixed with water. Only after the foam has settled can it be added to the solution.

The prepared solution is poured into the formwork, carefully leveled with a trowel and leveled to the level of the stretched nylon thread. The drying time of the foundation depends on weather conditions and is at least 3 days. Complete hardening of concrete occurs a week after pouring.

Frame construction

The stability of the future fence determines the quality of the frame. Its construction begins no earlier than 3 days after the foundation is poured. The construction of the frame can be done both before laying out the brick columns and after the construction.

The construction of the frame before the erection of brick pillars is carried out using a 20x40 profile pipe. The pipes are welded to the installed metal posts using welding. Horizontal pipes are welded at a distance of 30 cm from the top of the column and at a distance of 15 cm from the surface of the foundation. It is recommended to cover the manufactured frame alkyd paint, which will prevent metal corrosion.

In the second case it is necessary to installed pipes At a distance of 30 cm from the surface of the formwork and the top of the pipe, weld embedded metal plates that are brought out to the outside of the brickwork. In other words, the mortgages must protrude from the brickwork. After laying the pillars, cross members from a profile pipe are welded to the protruding mortgages.

Laying brick pillars

For lining installed metal supports facing bricks are used. Brick laying is done using cement mortar with a cement to sand ratio of 1 to 3. You can also add liquid soap to the mortar, which will improve its ductility.

The bricks are laid around an installed metal pole. Formed between the pillar and brickwork the gap is filled with solution. To strengthen the masonry, it is allowed to reinforce each two rows with a 50x50x4 mm mesh.

Advice! It is advisable to lay the pillars one by one: first lay the first pillar to a height of 50-60 cm, then the next one. This will allow time for the brickwork to shrink.

In places where profile pipes interfere with the masonry, the brick should be carefully cut with a grinder, then fit it under the pipe, carefully sealing all the cracks with cement mortar. To give the brick pillars a finished look, special ready-made caps are installed on top or I make them myself from galvanized steel.

Purchased in hardware store the caps are installed on the mortar, and made of galvanized steel, they are attached with dowels to the last brick row. Such caps can be painted to match the corrugated sheeting to give them beauty.

Fastening corrugated sheets

The final stage of building a fence with brick posts is attaching corrugated sheets to the frame. For this, galvanized roofing screws or special rivet nails are used.

Fastening, as a rule, is made in each wave adjacent to the crossbar. To do this, use a drill to drill a hole in the corrugated sheet and the cross member, after which a self-tapping screw is screwed in or a nail is pressed with a rivet gun.

The sheets are laid one on one with a slight overlap.

When the last sheet of corrugated sheeting is attached to the frame, the work is completed. Thus, installing a fence made of corrugated sheets with brick posts is not so difficult if you follow the stages of its construction.